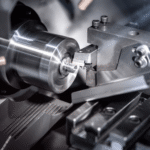

CNC Machining Services Precision Manufacturing for Industry

In today’s competitive manufacturing landscape, businesses demand high-quality, precise, and cost-effective production methods. CNC machining services have become the cornerstone of modern manufacturing, delivering consistent results for industries such as aerospace, automotive, medical, electronics, and more. With advanced technology and expert craftsmanship, companies can achieve complex geometries, tight tolerances, and efficient production runs that traditional methods cannot match.

This article explores the importance of CNC machining services, their applications, and how solutions like Custom CNC machining services, CNC milling and turning services, low volume CNC machining, and CNC prototyping services play a vital role in modern product development.

The Growing Importance of CNC Machining Services

The manufacturing world has shifted from manual machining to computer-controlled solutions. CNC machining services stand out because they provide:

-

Unmatched precision

-

Faster production cycles

-

Reduced human error

-

Versatility in material handling

With the rise of automation, businesses can now scale production while maintaining the highest levels of quality. Whether for small parts or large-scale industrial components, CNC machining services ensure repeatability and reliability.

Custom CNC Machining Services: Tailored to Unique Needs

Every project has unique requirements. That’s why Custom CNC machining services are essential. Unlike standardized production, custom machining ensures that each part is manufactured according to specific designs, dimensions, and tolerances.

Benefits include:

-

Flexible design modifications

-

Support for prototype testing

-

Adaptability to specialty materials

-

Seamless scalability from prototype to mass production

With Custom CNC machining services, businesses no longer need to compromise between quality and customization. Instead, they get tailored solutions that fit their exact project needs.

CNC Milling and Turning Services: Versatility at Its Best

Among the most popular applications of CNC machining services are CNC milling and turning services. These processes allow manufacturers to create intricate parts with high precision.

-

CNC Milling: Perfect for complex shapes, slots, and cavities. Milling machines use rotary cutters to remove material and achieve exact specifications.

-

CNC Turning: Ideal for cylindrical parts. A lathe rotates the workpiece while cutting tools shape it with accuracy.

When combined, CNC milling and turning services provide unmatched versatility. From aerospace components to automotive shafts and medical implants, these processes meet a wide range of production requirements.

Low Volume CNC Machining: Cost-Effective and Flexible

For businesses that don’t require large-scale production, low volume CNC machining is the ideal solution. Instead of investing heavily in expensive tooling or high production runs, companies can get small batches manufactured quickly and affordably.

Advantages include:

-

Reduced costs for small orders

-

Faster lead times

-

Easier design modifications

-

Perfect for market testing and pilot runs

With low volume CNC machining, businesses can test new designs, adjust specifications, and bring products to market faster without the financial burden of mass production.

CNC Prototyping Services: Turning Ideas into Reality

Before moving to full-scale production, prototyping plays a crucial role. CNC prototyping services allow businesses to transform digital designs into tangible parts. These prototypes help validate concepts, test functionality, and ensure accuracy before committing to larger runs.

Why choose CNC prototyping services?

-

Faster turnaround compared to traditional methods

-

High-quality prototypes with production-level accuracy

-

Ability to test multiple design iterations

-

Lower risk during product development

With CNC prototyping services, companies can confidently refine their designs and accelerate the product development cycle.

Precision Machining Services: Delivering Accuracy and Quality

At the heart of CNC machining services lies precision. Precision machining services are designed to meet the strictest tolerances, ensuring every component fits and functions perfectly.

Industries such as aerospace, defense, and medical devices require extreme accuracy, where even the slightest error can lead to failure. That’s why precision machining services are trusted for high-stakes applications.

Key advantages include:

-

Consistent quality in every batch

-

Tight tolerances down to microns

-

Compatibility with complex materials

-

Enhanced durability of finished parts

By combining advanced machinery with expert craftsmanship, precision machining services set the gold standard in modern manufacturing.

Applications of CNC Machining Services Across Industries

The versatility of CNC machining services makes them indispensable across multiple industries:

-

Aerospace: Manufacturing turbine blades, engine components, and structural parts with absolute accuracy.

-

Automotive: Producing engine parts, transmission components, and custom prototypes.

-

Medical: Creating surgical tools, orthopedic implants, and medical device housings.

-

Electronics: Fabricating enclosures, heat sinks, and custom connectors.

-

Industrial Equipment: Crafting gears, shafts, and heavy-duty machinery parts.

Each sector benefits from the speed, flexibility, and precision that CNC machining services deliver.

Why Choose Professional CNC Machining Services?

When selecting a partner for CNC machining services, businesses should prioritize:

-

Experience with complex projects

-

Advanced equipment and technology

-

Ability to provide Custom CNC machining services

-

Flexibility in low volume CNC machining and high-volume production

-

Expertise in CNC milling and turning services

A trusted provider ensures high-quality parts, faster lead times, and cost-effective solutions that align with business goals.

Future of CNC Machining Services

With advancements in automation, robotics, and AI integration, the future of CNC machining services looks even brighter. Smart factories, predictive maintenance, and enhanced machine learning capabilities will further boost efficiency and reduce downtime.

Additionally, sustainability efforts are driving eco-friendly machining practices, making CNC machining services not only more advanced but also more responsible toward the environment.

Conclusion

From Custom CNC machining services to CNC prototyping services, and from CNC milling and turning services to low volume CNC machining, modern manufacturing relies heavily on the versatility and precision of CNC machining services. These solutions empower businesses to bring ideas to life, scale production efficiently, and achieve unmatched quality across industries.

As industries continue to evolve, the demand for high-quality CNC machining services will only grow, ensuring that precision, customization, and innovation remain at the heart of global manufacturing.

English

English