Ceramic CNC Machining Precision Solutions for Complex Components

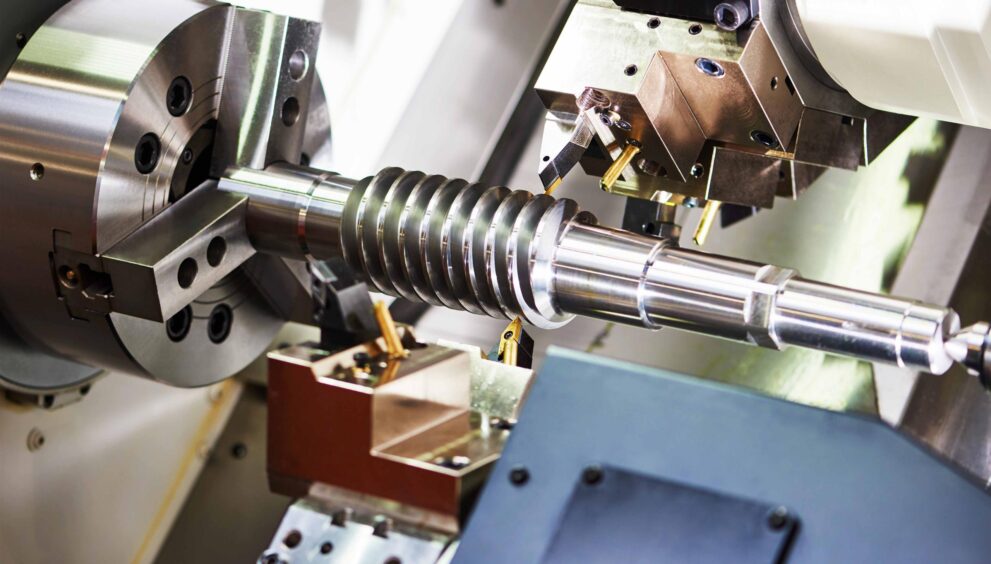

Ceramic materials are increasingly used across industries for their strength, heat resistance, and durability. However, these same properties also make ceramics very difficult to machine. Traditional methods often fall short when trying to achieve clean edges, tight tolerances, or complex geometries in ceramic components. That’s why Ceramic CNC Machining has become essential for manufacturers who need accuracy and reliability when working with advanced ceramic parts. Through specialized equipment, expert programming, and the use of diamond tools, CNC machining makes it possible to produce high-performance ceramic components at scale.

Why Ceramics Require Specialized CNC Machining

The Challenges of Machining Ceramics

Ceramic materials are incredibly hard and brittle. Unlike metals, they don’t bend under pressure—they crack. This creates a unique set of challenges for machinists. Even small vibrations or excessive force can damage the part or break a cutting tool. Ceramics also have low thermal conductivity, which makes heat buildup a serious issue during machining.

To overcome these challenges, CNC machining of ceramics requires precise control of every movement and condition. From the spindle speed to the type of coolant used, each element must be tailored to minimize stress on the material. This is only possible with modern CNC systems designed to handle difficult-to-machine materials like ceramics.

Precision for Critical Applications

Ceramic parts are used in industries where failure is not an option. These include aerospace insulators, semiconductor components, biomedical implants, and electronic substrates. Each of these applications demands extreme accuracy, dimensional stability, and smooth finishes.

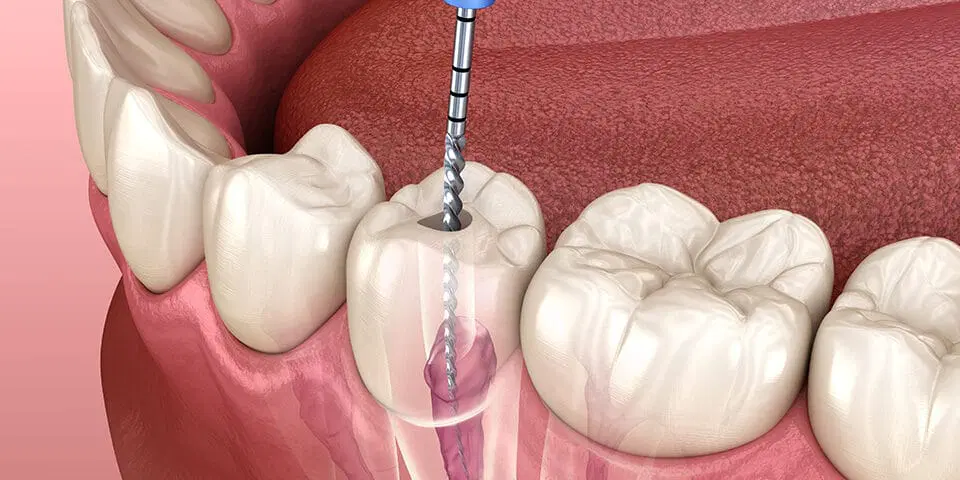

CNC machines make it possible to meet these expectations by providing tight tolerances and repeatable processes. Whether it’s drilling micro-holes, shaping intricate profiles, or grinding to sub-micron accuracy, CNC technology allows manufacturers to create ceramic components that consistently meet high standards.

Techniques and Tools for CNC Machining Ceramics

Diamond-Coated Tools and Grinding Methods

One of the most critical aspects of ceramic CNC machining is tool selection. Standard carbide tools cannot handle ceramic hardness. Instead, machinists rely on diamond-coated tools, which offer the hardness and thermal resistance needed to cut ceramics effectively without early wear.

CNC grinding is also widely used. It is ideal for achieving very fine finishes and precise tolerances. Unlike conventional machining, grinding applies less force and offers more control, which helps avoid cracks or edge chipping. This makes it perfect for final finishing or shaping flat and complex ceramic surfaces.

High-Speed Spindles and Accurate Fixturing

Another key requirement for machining ceramics is vibration control. Even slight motion irregularities can ruin a ceramic part. That’s why high-speed, low-vibration spindles are used in CNC machines built for ceramics. These spindles maintain smooth movement and stable cutting conditions throughout the process.

Fixturing is just as important. Ceramic parts must be securely held during machining without applying too much pressure. Vacuum fixtures, padded clamps, or custom jigs are often used to hold delicate parts in place. Proper fixturing not only prevents breakage but also improves the accuracy of every cut or grind.

Coolant and Air-Cutting Considerations

Heat is a major concern when machining ceramics, but many coolants can contaminate certain ceramic materials. For this reason, air-cooling or mist systems are often used instead of liquid coolants. These methods reduce heat buildup without introducing chemicals or moisture that might affect the part’s integrity.

In some cases, dry cutting is preferred, especially when working on medical-grade ceramics or components that require post-machining thermal treatments. CNC programs are adjusted accordingly to ensure speeds, feeds, and cutting paths account for heat management.

Benefits of Choosing Expert Ceramic CNC Machining Services

Consistent Quality with Minimal Waste

Ceramic materials are expensive, and errors during machining often result in scrapped parts. CNC machining dramatically reduces this risk. With accurate tool paths and repeatable processes, every part is produced consistently. This means less material waste, fewer errors, and lower overall production costs.

Expert machining services also use advanced inspection systems to verify tolerances and surface finish during and after production. This allows for real-time quality assurance and fewer rejected parts at the end of the process.

Faster Turnaround and Scalability

Time-to-market is critical in many industries. CNC machining provides a fast path from design to final product without the need for molds or castings. Once a CAD file is ready, the machine can begin production within hours. This is especially useful for prototyping or small production runs.

When it’s time to scale, the same CNC setup can be used to produce thousands of identical parts with no loss in quality. This flexibility makes CNC machining ideal for both one-off pieces and long-term production contracts involving ceramic components.

Innovation and Custom Design Capability

CNC machining allows for the creation of highly customized ceramic parts. Whether it’s a unique medical implant, a custom electronic insulator, or a complex aerospace component, CNC processes can follow any digital design. Engineers are free to innovate without being limited by traditional manufacturing constraints.

For industries that require constant innovation and product evolution, the ability to rapidly prototype and produce functional ceramic parts is a competitive advantage. Ceramic CNC machining gives manufacturers the tools to keep up with new demands and evolving technologies.

Conclusion: Precision Engineering for Advanced Ceramics

Ceramics offer unmatched performance in heat, wear, and corrosion resistance—but only if they’re manufactured with precision. With modern Ceramic CNC Machining, manufacturers can transform these challenging materials into accurate, reliable components ready for critical use.

Through the use of diamond tools, specialized grinding techniques, high-speed spindles, and careful fixturing, CNC technology provides a solution to the unique difficulties of machining ceramics. Whether for aerospace, medical, electronics, or defense, CNC machining offers the repeatability and accuracy that ceramic components require.

When choosing a machining partner, experience matters. Work with professionals who understand the nuances of ceramic materials and can deliver high-quality results every time. Precision, reliability, and trust—these are the hallmarks of expert ceramic CNC machining.

English

English