5 Axis Machining: Precision and Efficiency in Manufacturing

In today’s competitive manufacturing world, businesses are under constant pressure to deliver high-quality parts with faster turnaround times. Traditional machining methods, while still effective, often struggle to meet the demands of modern industries such as aerospace, automotive, and healthcare. This is where advanced technologies step in, with 5 axis machining leading the way. Known for its ability to produce highly complex parts with unmatched accuracy, this technology has revolutionized manufacturing standards worldwide. With the capability to reduce setups, minimize errors, and create intricate designs, 5 axis machining is more than just a solution—it’s a necessity for companies aiming to stay ahead.

Understanding the Fundamentals of 5 Axis Machining

What Exactly is 5 Axis Machining?

At its core, 5 axis machining is an advanced form of CNC (Computer Numerical Control) machining that allows tools or workpieces to move across five different axes simultaneously. While 3 axis machines operate along the X, Y, and Z axes, 5 axis machines add two rotational axes, enabling the tool to approach the material from virtually any angle. This reduces the need for multiple setups, saving time and improving consistency.

By eliminating manual repositioning, manufacturers not only achieve faster results but also ensure superior surface finishes and tighter tolerances, making this method indispensable for precision-driven industries.

How It Differs from 3 Axis Machining

3 axis machining is excellent for simple geometries, but it falls short for complex components. Multiple setups increase labor costs and raise the risk of errors. With 5 axis machining, even intricate designs can be completed in a single setup, greatly reducing production times and enhancing efficiency. This capability makes it ideal for producing parts with undercuts, deep cavities, or complex contours.

Applications of 5 Axis Machining Across Key Industries

Aerospace Components

The aerospace industry is one of the biggest beneficiaries of 5 axis machining. Aircraft components such as turbine blades, wing structures, and engine housings must be manufactured to incredibly strict tolerances. Even the smallest imperfection can compromise safety. 5 axis machining enables manufacturers to meet these requirements while also handling advanced materials like titanium and Inconel, which are notoriously difficult to cut.

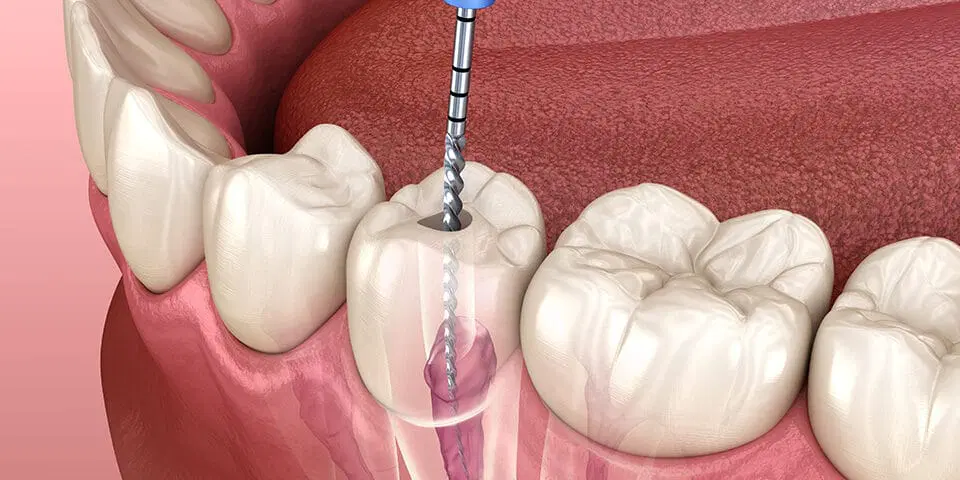

Medical Devices and Equipment

The healthcare sector demands precision and customization. Surgical tools, orthopedic implants, and dental prosthetics all require exact specifications and biocompatible materials. 5 axis machining makes this possible by delivering the accuracy needed for medical applications. Custom implants can be tailored to patient-specific needs, ensuring better outcomes and higher comfort levels. This level of precision would be impossible with traditional methods.

Key Advantages of 5 Axis Machining

Precision and Surface Quality

One of the most notable benefits of 5 axis machining is its ability to achieve superior accuracy. By minimizing repositioning and reducing handling, manufacturers maintain consistent dimensions while achieving smooth, high-quality finishes. This is particularly crucial in industries like aerospace and medical, where even microns matter.

Speed, Efficiency, and Cost Reduction

Efficiency is at the heart of 5 axis machining. By completing complex parts in fewer setups, production times are drastically reduced. This efficiency translates into lower labor costs, less material waste, and faster delivery schedules. For companies managing high-volume orders or tight deadlines, these advantages provide a competitive edge.

Why Choose MYT Machining for 5 Axis Solutions

When selecting a manufacturing partner, expertise and reliability matter just as much as technology. MYT Machining has established itself as a leader in delivering advanced 5 axis machining services for industries such as aerospace, medical, automotive, and industrial equipment.

What sets MYT apart is its combination of cutting-edge machinery, skilled technicians, and a commitment to quality. The company understands that every project has unique requirements, and it provides customized solutions that meet strict tolerances while maintaining efficiency. Clients benefit not just from advanced capabilities, but from a team that values long-term partnerships and continuous innovation.

The Future of 5 Axis Machining

Integration with Automation and Smart Manufacturing

As manufacturing embraces Industry 4.0, 5 axis machining is becoming even more powerful when combined with automation and smart technologies. Machines integrated with sensors and AI-driven software can now perform predictive maintenance, optimize tool paths, and improve scheduling. This increases uptime and efficiency while reducing unexpected downtime.

Expanding into Emerging Industries

While aerospace and medical sectors currently dominate the adoption of 5 axis machining, other industries are rapidly recognizing its potential. Electric vehicles, renewable energy, robotics, and defense applications are increasingly demanding complex, high-precision components. From producing battery housings for EVs to advanced gears for robotics, the versatility of 5 axis machining continues to expand its influence.

Conclusion

In the ever-evolving world of modern manufacturing, 5 axis machining has emerged as a cornerstone technology that enables precision, efficiency, and innovation. Its ability to handle complex geometries, deliver superior finishes, and reduce costs makes it invaluable across industries such as aerospace, automotive, and healthcare. For businesses aiming to stay competitive in a global marketplace, embracing 5 axis machining is no longer optional—it’s essential.

English

English