Why Rotary Lobe Pumps Are Preferred for Viscous Liquids

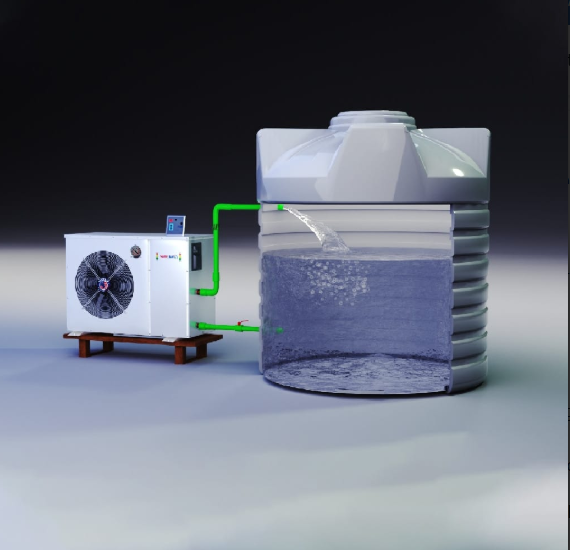

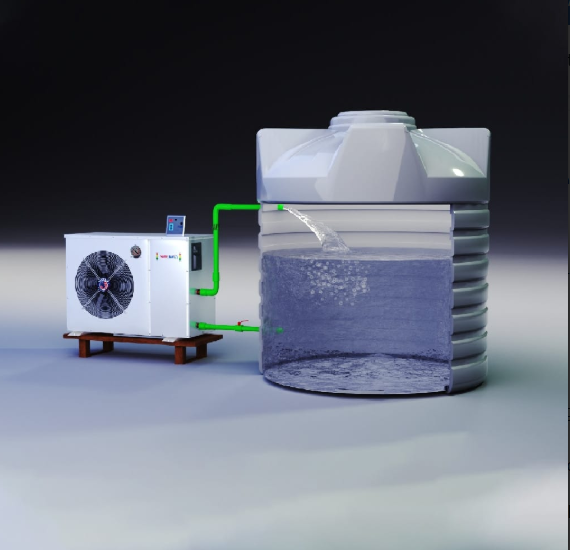

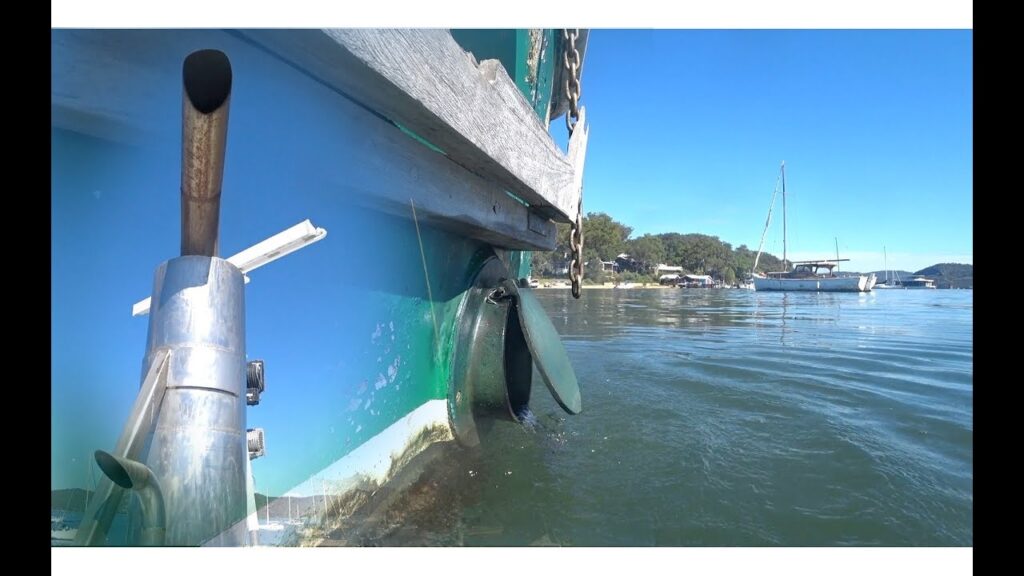

Rotary lobe pumps are a highly efficient solution for handling viscous liquids, making them the preferred choice across various industries. These pumps utilize intermeshing lobes that rotate within a casing, ensuring smooth and continuous fluid transfer. Their ability to handle thick, sticky, and shear-sensitive liquids with minimal pulsation sets them apart from other pump types.

The design of a rotary lobe pump allows for precise and controlled fluid movement, reducing energy consumption and maintenance costs. These pumps are particularly beneficial in industries like food and beverage, pharmaceuticals, and chemical processing, where maintaining the integrity of high-viscosity fluids is crucial.

Superior Efficiency in Handling Viscous Liquids

One of the primary reasons rotary lobe pumps are preferred for viscous liquids is their ability to maintain consistent flow rates without clogging. Unlike centrifugal pumps, which struggle with high-viscosity materials, rotary lobe pumps operate effectively even with the most challenging fluids. Their positive displacement mechanism ensures that fluids are moved efficiently, regardless of changes in viscosity.

Furthermore, rotary lobe pumps generate minimal shear stress, which is essential when dealing with delicate products such as creams, gels, and emulsions. This characteristic makes them indispensable in industries where maintaining product consistency and quality is paramount.

Hygienic and Easy-to-Clean Design

Industries such as food processing and pharmaceuticals demand pumps that adhere to strict hygiene standards. Rotary lobe pumps meet these requirements due to their sanitary design, which includes smooth internal surfaces and minimal dead zones. These features prevent bacterial growth and facilitate easy cleaning, making them suitable for applications requiring strict hygiene protocols.

Additionally, many rotary lobe pumps are designed to support clean-in-place (CIP) and sterilize-in-place (SIP) procedures. This capability reduces downtime and maintenance efforts, ensuring uninterrupted production while maintaining compliance with health and safety regulations.

Versatility Across Multiple Industries

Rotary lobe pumps are not limited to one industry; their versatility allows them to be used in a wide range of applications. In the food and beverage industry, they efficiently handle thick substances such as honey, molasses, and dairy products. Their gentle handling of fluids ensures that delicate ingredients maintain their texture and quality.

In the chemical and pharmaceutical industries, rotary lobe pumps are instrumental in transferring high-viscosity materials such as resins, adhesives, and medicinal creams. Their ability to handle aggressive chemicals while maintaining a consistent flow rate enhances operational efficiency and product reliability.

Durability and Cost-Effectiveness

Investing in a rotary lobe pump offers long-term benefits due to its durable construction and low maintenance requirements. These pumps are built to withstand demanding conditions and can handle abrasive and corrosive fluids without significant wear and tear. Their robust materials, such as stainless steel and specialized coatings, extend their operational lifespan.

From a cost perspective, rotary lobe pumps provide excellent return on investment. Their energy-efficient design reduces operational costs, while their minimal maintenance needs lower downtime and repair expenses. These benefits make them a cost-effective choice for businesses looking to improve productivity and reduce overall expenditures.

Conclusion

The rotary lobe pump stands out as an ideal solution for handling viscous liquids across various industries. Its ability to maintain consistent flow rates, ensure hygienic operations, and handle diverse applications makes it a preferred choice. Additionally, its durability and cost-effectiveness further enhance its value, making it a reliable investment for businesses. As industries continue to demand efficient and high-performance pumping solutions, the rotary lobe pump remains a top contender for managing challenging fluid-handling needs.

English

English