Shell and Tube Heat Exchangers For Modern Industry

In the full-size panorama of industrial operations, numerous components quietly carry out important obligations with out drawing a lousy lot of attention. One such component is the shell and tube heat exchanger, a critical tool in endless industries, from power technology to chemical processing, HVAC systems, or maybe meal production. Despite their unassuming nature, those warmth exchangers play a pivotal function in preserving power overall performance, ensuring protection, and optimizing overall performance in industrial techniques. Without them, industries might struggle to adjust the temperature, switch warmth successfully, and manipulate operational prices effectively.

As strength needs retained to upward thrust globally, the importance of shell and tube warm temperature exchangers has best grown. These systems are engineered to stand as much as excessive situations and deal with large volumes of heat transfer, making them imperative inside the modern enterprise ecosystem. Comprehending their layout, feature, and programs illuminates their significance because the unsung heroes of present day industry.

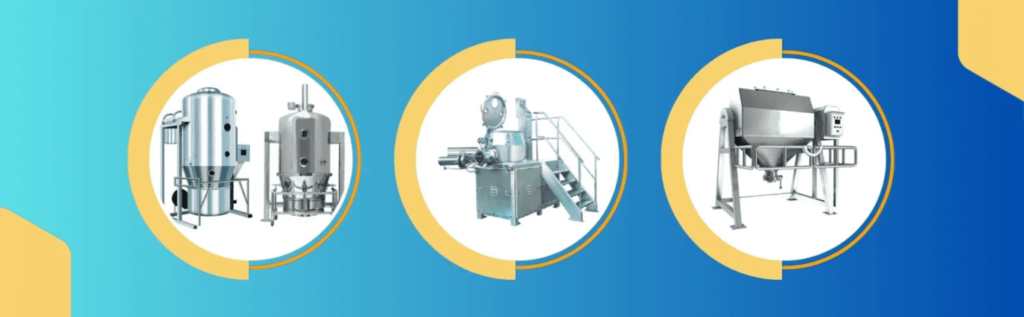

The Fundamentals of Shell and Tube Heat Exchangers

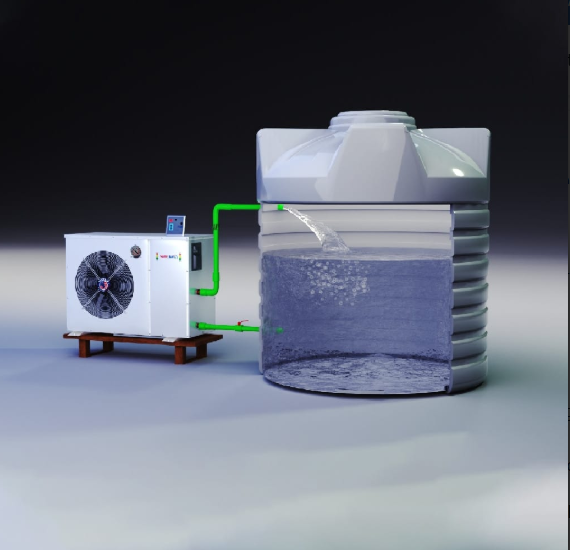

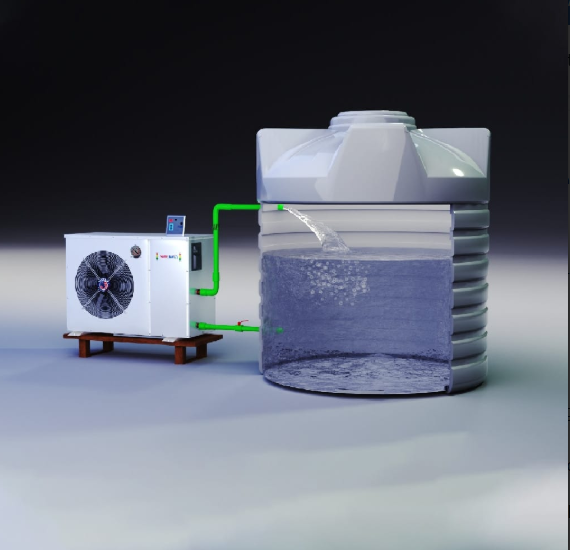

Shell and tube warmth exchangers are designed to transfer warmness among fluids, commonly one which flows via tubes and some different that surrounds those tubes inner a bigger shell. The fundamental precept consists of one fluid soaking up or dissipating heat because it actions via the device, facilitating efficient thermal change.

The creation of these exchangers includes a shell, a bundle deal of tubes, and different supporting components like baffles and tube sheets. The heat fluid flows via one set of passages even as the bloodless fluid flows thru the alternative, separated by using the usage of the tube partitions. This format permits for effective heat switch whilst retaining a immoderate degree of durability and reliability, even below high-stress conditions.

Applications Across Industries

One of the primary reasons shell and tube warmth exchangers are so extensively used is their adaptability across a couple of industries. Their robust format allows them to address a number of fluids, such as corrosive chemicals, steam, or maybe cryogenic materials.

Power Generation

In power plant life, warmth exchangers are vital for regulating temperatures in mills, condensers, and boiler systems. They assist convert steam returned into water, enhancing widespread performance and ensuring a non-stop energy cycle. Their capacity to address excessive pressures and temperatures makes them a staple in energy era centers worldwide.

Chemical and Petrochemical Industry

The chemical enterprise is based totally intently on specific temperature manage to facilitate reactions, distillation, and refining approaches. Shell and tube warmth exchangers are used to kick back and heat various chemicals, making them important to operations in refineries, petrochemical flora, and pharmaceutical production.

HVAC and Refrigeration Systems

Heating, air flow, and air conditioning (HVAC) structures contain warmth exchangers to modify indoor climates efficiently. By transferring warm temperature amongst refrigerants and water or air, these structures hold most suitable temperature control in buildings, ensuring comfort and power performance.

Food and Beverage Processing

Food industries require normal temperature manipulate to keep products and hold satisfactory. Shell and tube warm temperature exchangers are used in dairy pasteurization, brewing, and different meals-processing programs where warmth exchange is crucial for protection and performance.

Advantages of Shell and Tube Heat Exchangers

The cause shell and tube warm temperature exchangers maintain to dominate commercial packages lies in their severa benefits:

High Efficiency and Versatility

These exchangers offer extraordinary warmth transfer performance due to their massive floor region and ability to deal with brilliant styles of fluids. They are also versatile, capable of being custom designed primarily based at the specific warmness switch necessities of different industries.

Durability and Reliability

Constructed from substances which includes stainless-steel, titanium, and specific corrosion-resistant alloys, shell and tube warmness exchangers are designed to undergo excessive situations. Their sturdy build lets in them to characteristic in immoderate-strain and excessive-temperature environments with out substantial put on and tear.

Ease of Maintenance and Cleaning

One of the important advantages of this warmth exchanger type is its ease of safety. The tubes may be cleaned or modified without dismantling the whole machine, lowering downtime and operational disruptions. This characteristic is specifically valuable in industries wherein continuous operation is critical.

Scalability

Shell and tube warm temperature exchangers are to be had in various sizes and configurations, permitting industries to scale operations without transforming complete systems. Their modularity makes them a sensible choice for each small-scale and large-scale commercial packages.

Innovations in Heat Exchanger Technology

With improvements in substances generation and engineering, present day shell and tube heat exchangers have become more green and environmentally pleasant. Enhanced tube designs, together with finned and corrugated tubes, enhance warm temperature switch prices at the same time as minimizing fouling. Smart tracking structures now allow actual-time information monitoring, optimizing basic overall performance and lowering electricity waste.

Additionally, industries are exploring nanotechnology coatings that beautify resistance to scaling and corrosion, prolonging the lifespan of heat exchangers. These improvements hold to drive overall performance upgrades, making shell and tube warm temperature exchangers more fundamental to commercial enterprise sustainability.

Conclusion

Shell and tube warmth exchangers might not accumulate the recognition they deserve, but their effect on current enterprise is plain. From strength manufacturing and chemical processing to HVAC systems and meals manufacturing, those flexible gadgets make sure inexperienced thermal control and operational stability. Their durability, performance, and adaptability cause them to an essential component in severa sectors, proving that they will be certainly the unsung heroes of current enterprise.

As industries try to improve performance and decrease environmental effect, heat exchangers will keep to comply, incorporating new technology and sustainable answers. Whether in a electricity plant, a refinery, or a industrial air conditioning system, those reliable warmth exchangers quietly resource the spine of contemporary-day commercial strategies, making sure seamless operations for future years.

English

English