Why Expert Engineering Design Matters in Automation Tooling

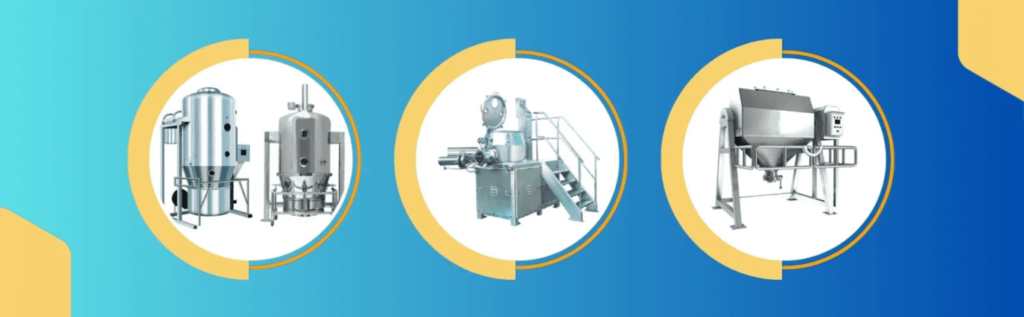

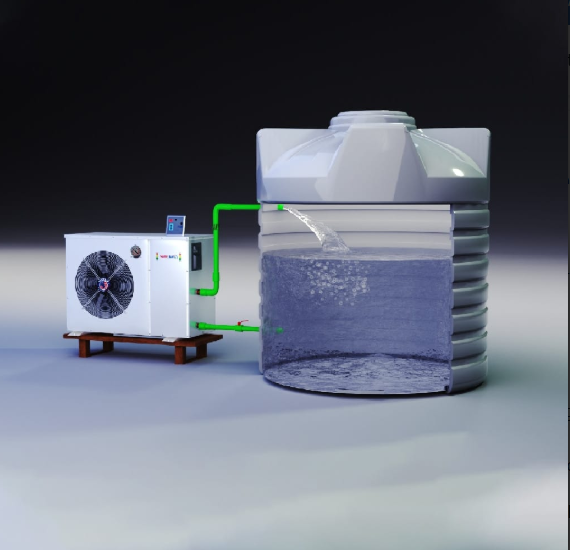

In the world of automation, precision and efficiency are paramount. Automation tooling, the essential components and machines that facilitate automated production, is crucial to the success of many industries, from manufacturing to logistics. However, the foundation of effective automation tooling lies in expert engineering design. Without a tailored, well-thought-out design, automation systems can underperform, lead to inefficiencies, and even break down. This is where expert engineering design becomes a game-changer.

Whether you’re looking to streamline your manufacturing processes, reduce costs, or enhance the functionality of your tooling, expert engineering design can make all the difference. A bespoke engineering design approach ensures that your tooling is perfectly suited to your specific needs, maximizing both performance and productivity.

In this article, we’ll explore the key reasons why expert engineering design is so vital in automation tooling, and how it contributes to success in automation projects.

1. The Importance of Engineering Design in Automation Tooling

Creating Customized Solutions for Unique Needs

When it comes to automation tooling, one-size-fits-all solutions rarely work. Every company has different requirements, whether it’s the scale of the operation, the type of products being produced, or the specific challenges faced in the production process. Expert engineers design custom solutions tailored to the precise needs of your business. This bespoke design approach allows for maximum efficiency, better integration with existing systems, and a perfect fit for the intended application.

Optimizing Tooling for Performance

A skilled engineering design process ensures that the tooling is designed to deliver peak performance. Engineers focus on optimizing every element, from materials used to the overall design structure. The result is tooling that runs smoothly, reduces downtime, and delivers high throughput.

2. Improving Productivity and Efficiency

Reducing Downtime and Maintenance Costs

Tooling that’s poorly designed can result in frequent breakdowns and costly downtime. Expert engineering design ensures that each component of the automation tooling is robust, efficient, and less prone to failure. This leads to fewer maintenance needs, longer-lasting components, and a significant reduction in downtime. The result? Increased productivity and less interruption in your workflow.

Streamlining Manufacturing Processes

Well-designed automation tooling can streamline your manufacturing processes, making them more efficient. Expert engineers take into account how different parts of the system interact, designing tools that facilitate faster production times and fewer manual interventions. This means your production lines will run at higher speeds and with greater consistency.

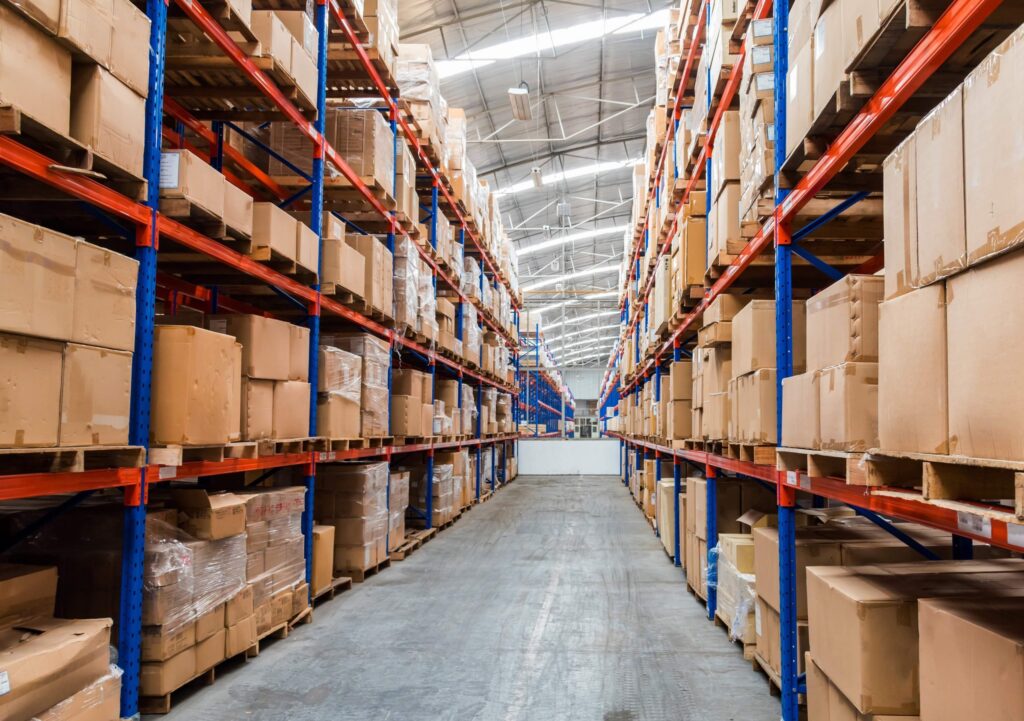

3. Enhancing Scalability in Automation Tooling

Accommodating Future Growth

As your business grows, your automation systems will need to scale accordingly. Expert engineering design ensures that your automation tooling is not just suited to your current needs but also capable of adapting to future expansions. Whether you need to increase production capacity or introduce new products, a flexible, scalable design will ensure that your tooling can grow with you.

Modular Designs for Easy Expansion

Expert engineers often utilize modular designs for automation tooling, allowing easy upgrades or the addition of new tools and capabilities. This type of design enables companies to modify their tooling as needed, reducing the time and costs involved in making significant changes to the system.

4. Cost Savings Through Expert Design

Reducing Material Waste

Engineering design plays a crucial role in minimizing material waste, which is a common issue in production processes. By optimizing tooling designs, expert engineers can ensure that the amount of material required is minimized, reducing costs and promoting more sustainable practices.

Lower Operational Costs

Well-designed tooling not only improves productivity but also contributes to lowering operational costs. Efficient automation tooling reduces the need for manual labor, cuts energy consumption, and eliminates inefficiencies in the production process. As a result, businesses can achieve significant cost savings over time.

5. Safety Benefits of Expert Tooling Design

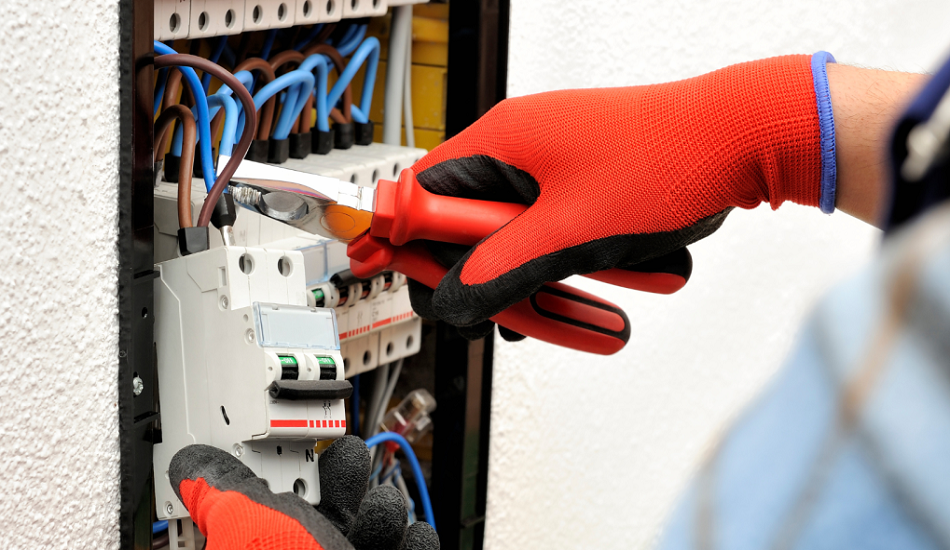

Minimizing Risk with Safety Features

Safety is always a priority in any industrial setting, and automation tooling is no exception. Expert engineers design tooling systems with safety features in mind, ensuring that they comply with relevant regulations and standards. From emergency shutoff mechanisms to proper guarding, a well-designed automation system prioritizes worker safety.

Reducing Workplace Accidents

Automation tooling that’s designed with precision can reduce human error and potential safety hazards. Expert engineering design helps ensure that the tools are easy to use, preventing accidents caused by malfunctioning or poorly designed equipment. By minimizing risk, businesses can protect workers and reduce liability.

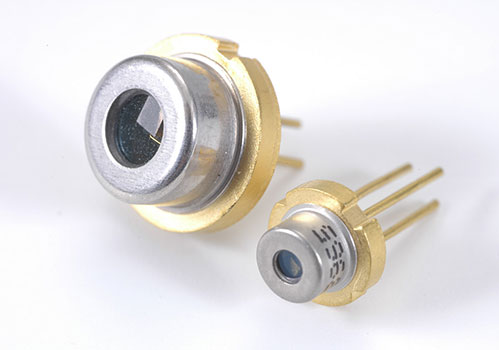

6. The Role of Precision in Automation Tooling

Ensuring High-Quality Output

In automation, precision is key to producing high-quality products consistently. Expert engineering design ensures that the tooling meets exact specifications and tolerances. This level of accuracy not only improves the quality of the output but also ensures that each part produced fits seamlessly with others in the system.

Minimizing Errors and Rework

By focusing on precision during the design phase, expert engineers can eliminate common issues like misalignments or inaccuracies, which can lead to costly rework and defects. Automation tooling that’s designed for high precision minimizes these errors, increasing the overall reliability of the production process.

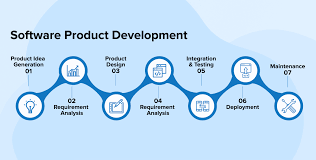

7. Innovation in Tooling Design for Automation

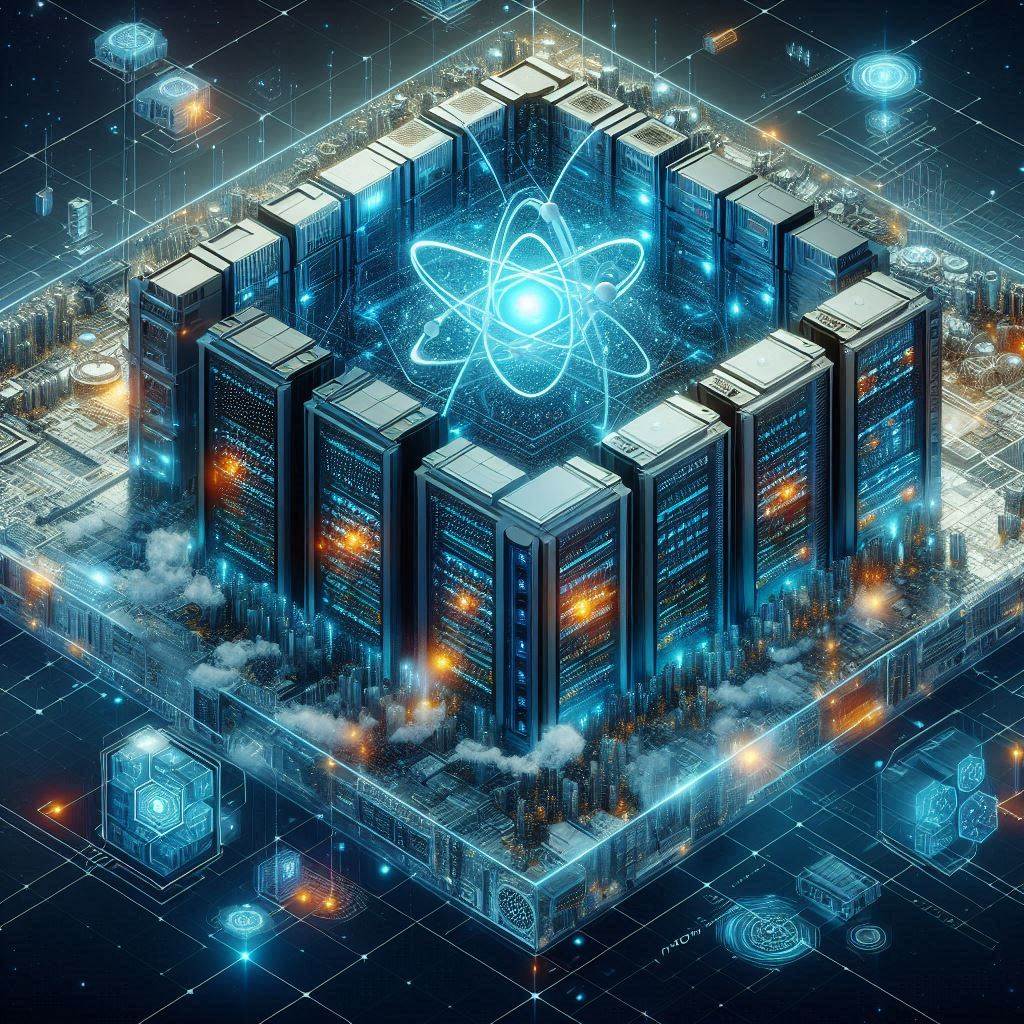

Adopting the Latest Technologies

The field of automation is constantly evolving, and staying ahead of the curve requires embracing new technologies. Expert engineers incorporate the latest advancements in materials, robotics, and artificial intelligence to create innovative tooling solutions. This allows businesses to remain competitive by improving the efficiency and capabilities of their automation systems.

Customization and Technological Integration

By opting for bespoke engineering design, companies can incorporate the latest technological innovations into their tooling. Whether it’s AI-powered machinery or robotic arms, customized designs allow for the seamless integration of new technologies into existing systems.

8. Improving Product Quality with Engineering Design

Designing for Consistency

Automation tooling plays a crucial role in ensuring product consistency. By using expert design techniques, engineers can ensure that each product manufactured is of the same high quality. This consistency is vital for businesses looking to maintain a strong brand reputation and meet customer expectations.

Minimizing Defects and Variability

With precise engineering design, tooling systems can reduce variability, ensuring that the final product is consistent and defect-free. Expert engineers focus on designing tooling that minimizes defects and improves overall product quality.

9. Supporting Environmental Sustainability

Eco-Friendly Materials and Practices

As the world becomes more conscious of environmental impact, the demand for sustainable practices in automation is on the rise. Expert engineering design can support sustainability by utilizing eco-friendly materials, optimizing energy efficiency, and reducing waste. This approach helps companies meet their environmental goals and reduces their carbon footprint.

Energy-Efficient Tooling

Another way expert engineering design can help is by creating energy-efficient tooling systems. By selecting components that consume less energy, engineers can design systems that are both cost-effective and environmentally friendly.

10. Future-Proofing Automation Tooling

Designing for Technological Advancements

The future of automation tooling is continuously changing with new technologies, tools, and processes. Expert engineering design ensures that automation systems are adaptable and can easily incorporate future advancements without needing a complete redesign.

Ensuring Long-Term Investment Value

A well-designed system doesn’t just perform well today—it remains valuable in the long term. Expert engineering design focuses on creating systems that are durable, easy to upgrade, and capable of handling future technological innovations. This ensures that the investment in tooling will continue to provide value over time.

Conclusion

Expert engineering design is integral to the success of automation tooling. From reducing costs and improving efficiency to enhancing safety and product quality, the benefits of customized engineering solutions are clear. By investing in bespoke engineering design, businesses can ensure that their automation systems are not only functional but also scalable, reliable, and innovative. Whether you’re just starting to implement automation or looking to improve an existing system, expert engineering design is key to achieving sustainable growth and success in the automation industry.

English

English

Office Clearance for SMEs: Affordable Solutions Businesses

Office Clearance for SMEs: Affordable Solutions Businesses