Why End Life Molded Pulp is the Future of Biodegradable Packaging

The world is facing an environmental crisis that demands swift and effective solutions. With plastic pollution reaching catastrophic levels and natural resources dwindling, the need for sustainable alternatives has never been more urgent. Packaging, especially plastic packaging, is a significant contributor to the growing environmental concerns. However, innovative materials like end life molded pulp are emerging as a promising solution. In this article, we explore why end life molded pulp is poised to become the future of biodegradable packaging, offering both environmental benefits and practical advantages for industries worldwide.

What is End Life Molded Pulp?

End life molded pulp refers to a specific type of molded pulp packaging material that is designed to be biodegradable and compostable at the end of its lifecycle. Molded pulp, which is traditionally made from recycled paper, cardboard, and other natural fibers, is formed into packaging products like trays, containers, and protective inserts. End life molded pulp distinguishes itself by incorporating sustainable design features, ensuring that the material does not contribute to environmental harm after it has been used. This makes it an ideal alternative to plastics, which can take hundreds of years to decompose in landfills.

The term “end life” emphasizes the biodegradable nature of the material, focusing on the fact that once the molded pulp product has served its purpose, it will break down naturally, causing minimal impact on the environment. Unlike traditional plastics, which persist in ecosystems, end life molded pulp decomposes swiftly and leaves behind no harmful residues. This environmental characteristic is vital as industries shift toward more sustainable practices to meet both consumer demand and regulatory requirements.

The Environmental Benefits of End Life Molded Pulp

End life molded pulp offers several environmental advantages that make it a clear contender for replacing plastic and other non-biodegradable packaging materials. One of the most compelling reasons for its adoption is its biodegradability. Molded pulp breaks down within a few months when exposed to natural elements, reducing the accumulation of waste in landfills and oceans. This property ensures that end life molded pulp does not contribute to long-term pollution, unlike plastic packaging, which can persist for centuries.

Additionally, molded pulp is made from renewable resources, such as recycled paper and natural fibers, which further reduces its environmental footprint. The production of end life molded pulp generally uses fewer chemicals and energy than plastic manufacturing processes, making it a more eco-friendly choice. As more businesses seek to reduce their carbon footprint and improve their sustainability efforts, the demand for biodegradable packaging like end life molded pulp is expected to grow significantly.

Versatility and Durability of End Life Molded Pulp Packaging

Another reason end life molded pulp is considered the future of biodegradable packaging is its versatility. The material can be molded into a wide variety of shapes and sizes, making it suitable for a range of packaging applications. From food containers and beverage holders to product packaging and shipping inserts, end life molded pulp can replace traditional packaging in various industries. Its ability to protect goods during transportation and storage makes it a viable option for both retail and e-commerce packaging solutions.

In addition to its versatility, end life molded pulp is durable and offers robust protection. While it may not be as rigid as some plastic materials, molded pulp is more than capable of providing adequate cushioning and structural integrity for fragile items. This combination of strength and environmental benefits gives molded pulp an edge over other biodegradable materials that may not provide the same level of protection or functionality. As industries increasingly prioritize sustainability without compromising on product safety, the demand for molded pulp is likely to grow.

Cost-Effectiveness and Accessibility of End Life Molded Pulp

Cost is often a deciding factor for businesses when choosing a packaging solution, and end life molded pulp proves to be both affordable and accessible. While the initial cost of molded pulp may be slightly higher than plastic, its overall cost-effectiveness comes from its ability to be recycled and reused. Moreover, the cost of manufacturing molded pulp has decreased significantly over the years, thanks to advances in production technology and the growing availability of raw materials.

The availability of end life molded pulp is also increasing as more companies and manufacturers embrace sustainable practices. The global push for more environmentally friendly products has led to greater investment in biodegradable packaging technologies. As a result, molded pulp is becoming more accessible to businesses of all sizes, particularly as demand for sustainable alternatives continues to rise. For companies looking to align their packaging strategies with environmental goals, end life molded pulp represents a cost-effective solution that can contribute to their long-term success.

The Future of End Life Molded Pulp in Global Markets

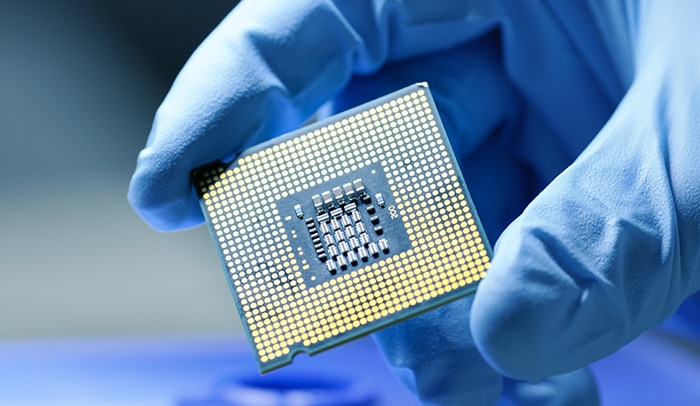

The global market for sustainable packaging is expected to grow rapidly in the coming years, and end life molded pulp is poised to play a significant role in this shift. Governments worldwide are implementing stricter regulations on plastic use, encouraging businesses to explore alternatives. The rise of eco-conscious consumers who demand greener products and packaging is also pushing companies to adopt more sustainable materials like molded pulp. As a result, industries such as food and beverage, electronics, and cosmetics are increasingly turning to end life molded pulp for their packaging needs.

Looking to the future, it is clear that end life molded pulp has the potential to revolutionize the packaging industry. With its environmental benefits, versatility, and cost-effectiveness, molded pulp presents a viable solution to the global challenge of plastic pollution. As technology advances and more companies commit to sustainable practices, the role of end life molded pulp will only continue to expand, making it a cornerstone of the future of biodegradable packaging.

In conclusion, end life molded pulp is emerging as the future of biodegradable packaging due to its numerous environmental, practical, and economic benefits. Its biodegradability, versatility, and cost-effectiveness make it an attractive alternative to traditional plastic packaging. As industries worldwide continue to prioritize sustainability, end life molded pulp is well-positioned to become a standard in eco-friendly packaging solutions. By adopting molded pulp, businesses can contribute to a cleaner planet while meeting the growing consumer demand for sustainable products and practices.

English

English

Office Clearance for SMEs: Affordable Solutions Businesses

Office Clearance for SMEs: Affordable Solutions Businesses