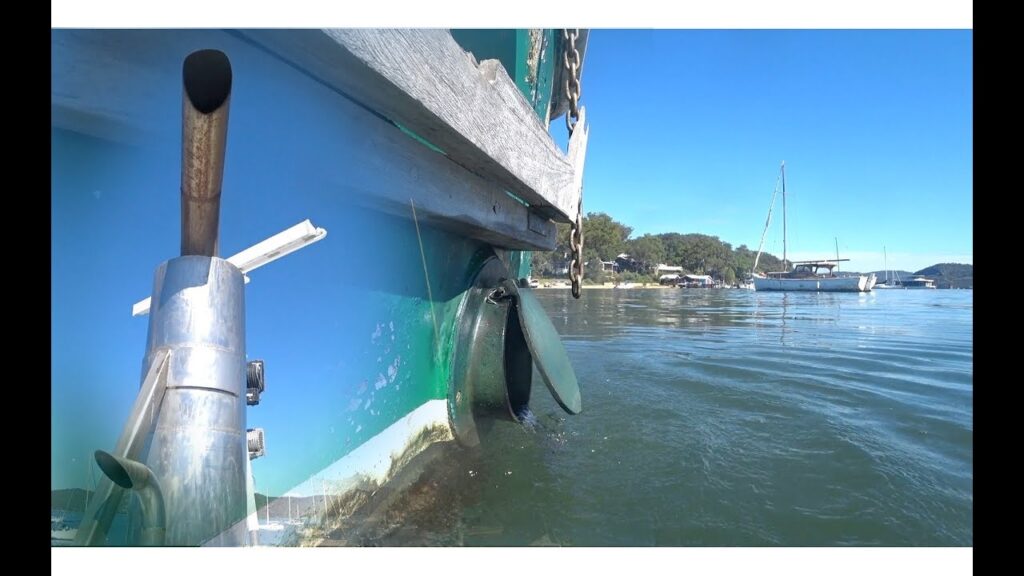

Where Can One Find a Trustworthy Supplier of Marine Air Compressors

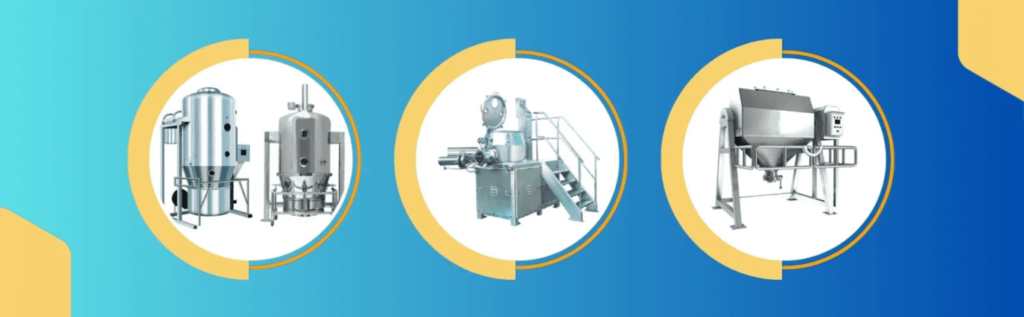

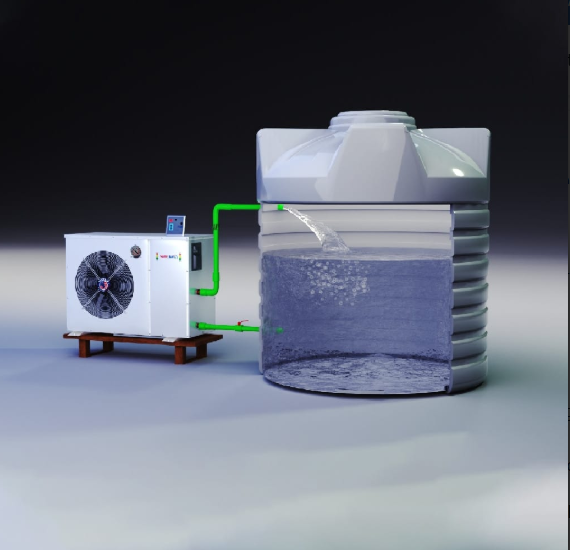

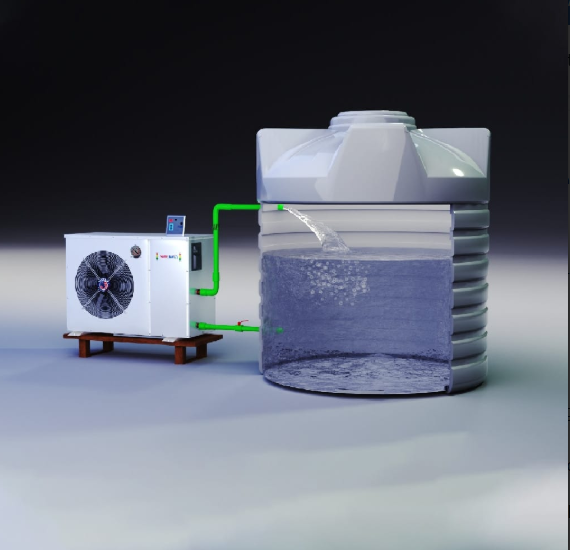

Marine air compressors are essential to ship operations because they provide effective engine operation and operate essential equipment. A thorough assessment of variables including product quality, dependability, and industry knowledge is necessary when looking for a trustworthy air compressor supplier for these compressors. Consistent performance, longevity, and adherence to maritime industry requirements are guaranteed by the appropriate provider.

Observance of Marine Industry Standards

Strict safety and performance requirements must be met by marine equipment to protect crew members and ship operations. Compressors sourced from reputable companies are approved by trade organizations and adhere to international maritime standards. High humidity, extremely high temperatures, and sustained performance under challenging conditions are all guaranteed by these criteria.

Availability and Product Selection

With the help of a reliable issuer, a wide selection of air compressors is provided to meet the requirements of various vessel kinds and operations. Customers can choose the appropriate equipment for their needs from a vast selection of options, portable devices to massive commercial compressors. It’s crucial to keep in mind the availability of substitute parts and gadgets when selecting a dealer.

Technical support and engineering expertise

Customers are guaranteed to receive expert help from a business with vast engineering experience when selecting, maintaining, and troubleshooting marine air compressors. Through the provision of installation guidance, operational training, and repair services, their technical guide teams ensure that compressors run at the best quality and efficiency for the duration of their lives. Simple customer service is easier to access, which reduces the risk of downtime and operational errors.

A Look at Some Factors When Choosing a Supplier

The selection of a marine air compressor supplier requires careful consideration of many important factors. The background, reputation, and ability to offer customized solutions all impact the dealer’s dependability and credibility.

Proficiency in the Marine Industry

Shipboard air compression systems have specific needs, which suppliers with extensive maritime enterprise experience are aware of. Their extensive business expertise enables them to offer products that may be most suited for maritime environments, ensuring durability and consistent performance. They can suggest the best compressors for various vessel types because of their knowledge of maritime laws and difficulties.

Manufacturing and Material Quality

Marine air compressors are indeed built using top-grade materials to ensure that they are able to withstand the rigors and environments of the sea. Advanced sealing technology, corrosion-resistant coatings, and stainless steel components increase compressor durability. A reliable supplier will prioritize high production standards, ensuring every unit is engineered for maximum reliability and efficiency.

Performance and Energy Efficiency

For marine operations, where cost control depends heavily on efficiency, energy consumption is a major concern. Energy-efficient high-performance air compressors lower operating expenses and fuel usage. Compressors with cutting-edge technology from a reputable provider maximize airflow, reduce heat loss, and boost overall efficiency.

Accessibility of Maintenance Services and Spare Parts

Regular maintenance is required to keep marine air compressors running up to the mark. A trusted source of genuine parts ensures that worn-out components can be replaced efficiently and simply. By guaranteeing long-term compressor dependability, suppliers who provide thorough maintenance plans and repair services enhance value.

The Value of Post-purchase Assistance

After-sales support from a supplier is also an important factor that influences the reliability of marine air compressors. Comprehensive assistance includes routine inspections, emergency repairs and technical expertise. Suppliers who place a high priority on post-purchase assistance guarantee that ships have little downtime and always operate efficiently.

Service and Warranty Contracts

Reputable vendors put warranties alongside service contracts in their compressors to last longer and perform better. These contracts reduce the risk of unforeseen failures by scheduling maintenance, repair services, and part replacement. A robust warranty policy shows the supplier’s faith in their goods and dedication to client happiness.

Installation and Training onboard

This is another reason why you must get professional advice about marine air compressors and their installation/operation. Many suppliers offer training aboard to ensure that ship crew personnel all acquire knowledge of compressor operation, maintenance and troubleshooting. This proactive strategy improves the overall effectiveness of onboard equipment and reduces the chance of problems.

Worldwide Presence and Logistics Assistance

Logistics assistance is a crucial consideration when selecting a supplier because shipping operations frequently need rapid access to replacement compressors and spare parts. An international distribution network allows a supplier to deliver products and components to ports worldwide on time. Through quick turnaround times for urgent orders, they reduce operational disruptions and downtime.

There Are Regional Service Centers Available

To ensure that ships receive prompt assistance when they need it, providers with regional service centers provide localized support. Operational effectiveness is increased and delays caused by unforeseen technical issues are reduced when skilled technicians and replacement components are available in strategic locations.

Supply Chain Reliability

To ensure the uninterrupted availability of marine air compressors and their components, a robust supply chain is necessary. Customers can receive their orders on time when a reliable provider maintains a strong supply chain. This dependability is especially important for maritime operations because malfunctioning equipment must be replaced right away.

Personalization and Tailored Approaches

The size, purpose, and operational requirements of various vessels determine the specific requirements for air compression systems. Customers can customize compressors to meet certain technical and environmental requirements by using customization options provided by a reliable provider.

Flexibility in Meeting Vessel Requirements

For a smooth integration, marine air compressors need to work with the current onboard systems. Compressors can be altered by suppliers who provide bespoke solutions according to variables including operating capacity, power consumption, and available space. Customized solutions avoid compatibility problems and increase efficiency.

Integration of Advanced Technology

To enhance overall performance and efficiency, progressive providers incorporate cutting-edge technology into their air compressors. Automated pressure controls, real-time tracking, and remote diagnostics all contribute to overall reliability. Modern marine air compression systems are accessible if you choose a supplier who makes investments in technology.

Conclusion

When looking for a reliable marine air compressor supplier, it is important to carefully consider a number of factors, including the best product, industry knowledge, and after-income provider. Effectiveness and durability in challenging maritime settings are ensured by a reliable issuer providing high-performance compressors that adhere to maritime policies. Their dedication to logistics, technical assistance, and customer service guarantees seamless operations for ships of all sizes. Ship operators can maintain optimal air compression performance at sea, lower operating costs, and improve reliability by choosing a reliable provider.

English

English

Office Clearance for SMEs: Affordable Solutions Businesses

Office Clearance for SMEs: Affordable Solutions Businesses