What is the On Board Weighing System Price and its benefits

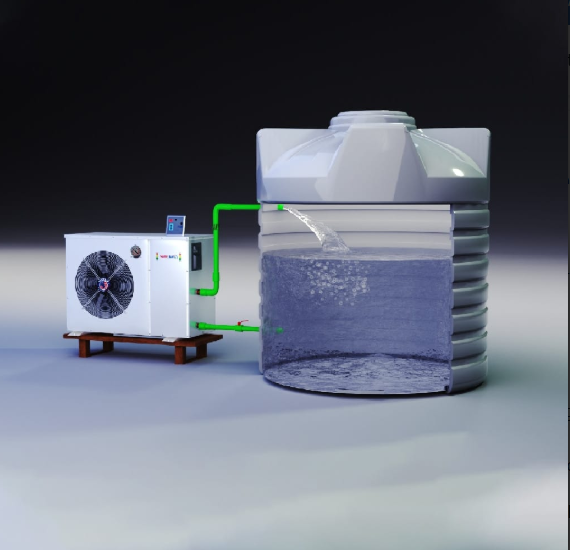

Efficient records control and unique weight measurement have emerged as vital components of operational success in trendy fast-paced industrial and business settings. Modern weighbridge scales, computerized weighing structures, and included weighing answers have modified how groups in a variety of industries manipulate weight measurement. Numerous benefits of these systems are examine, in conjunction with their outcomes on price manipulation and operational effectiveness.

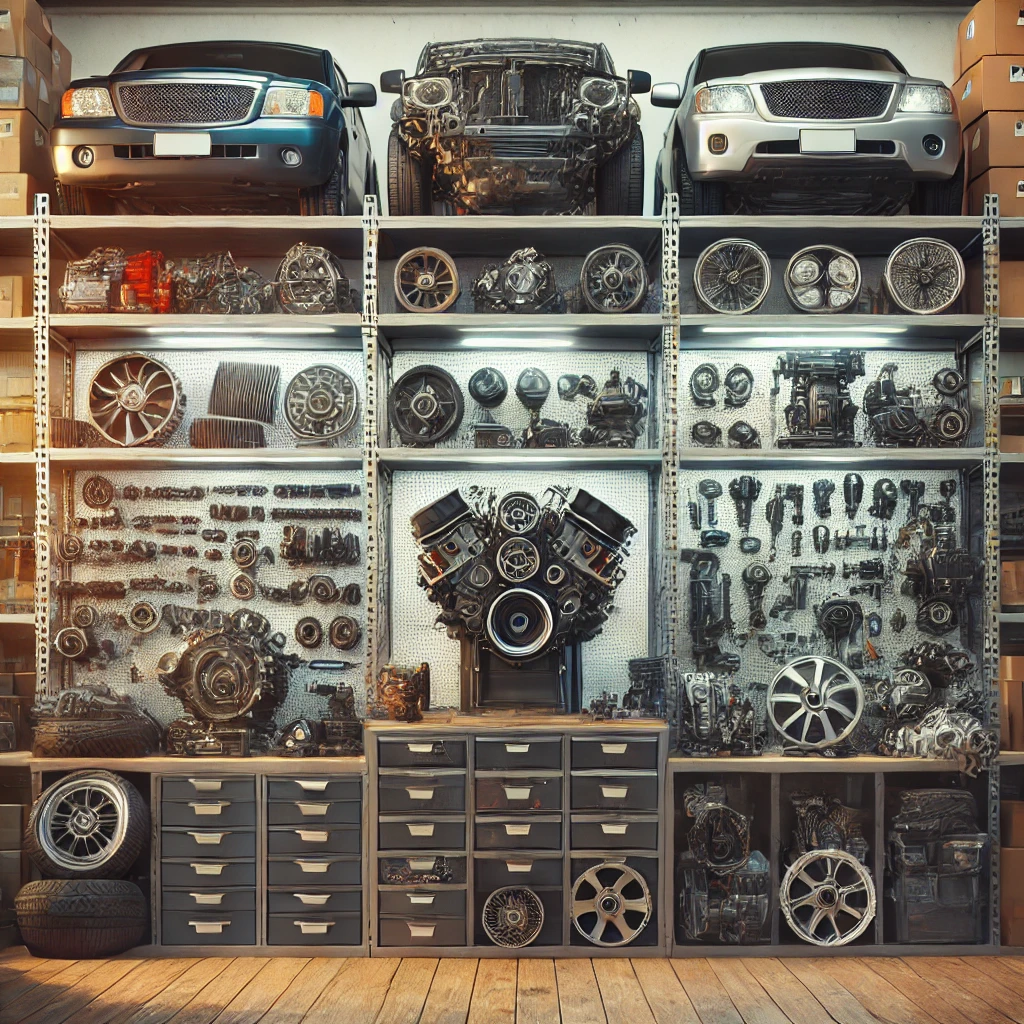

Recognizing the Main Advantages of Weighbridge Scales

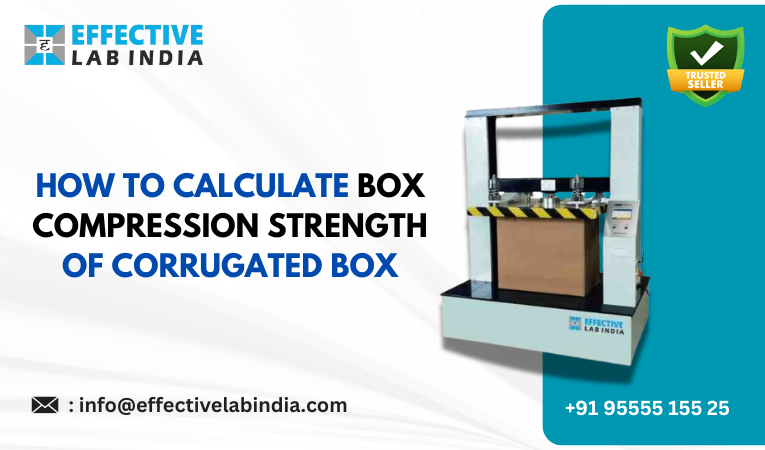

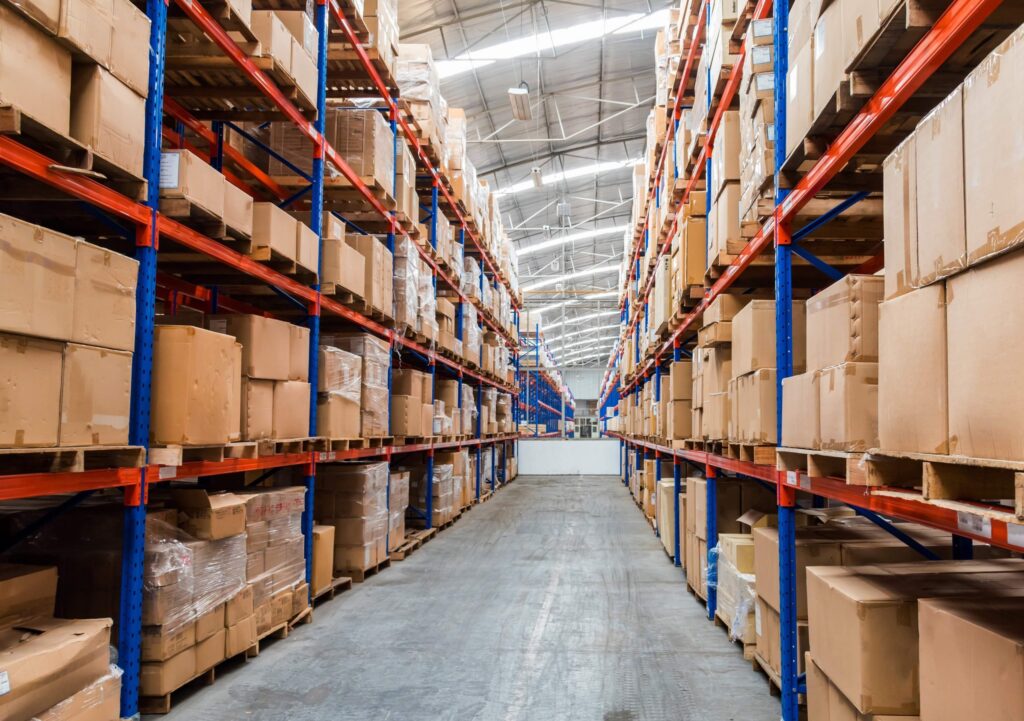

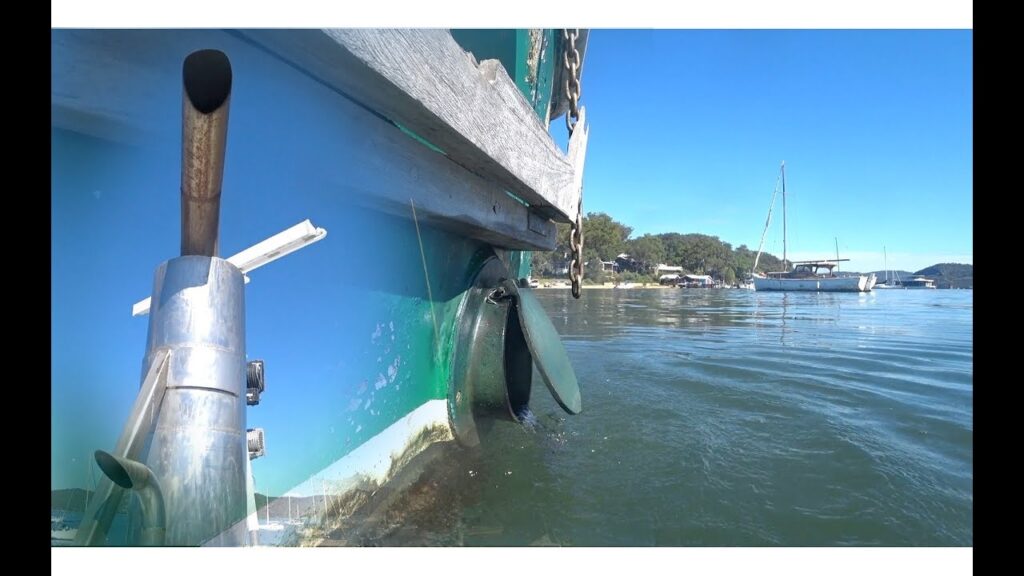

Truck scales, regularly referred to as platform scales or weigh bridge scale, are an essential part of present-day industrial weighing systems. With accuracy and dependability, these sturdy measurement devices can manage big weights and heavy vehicles. The capacity of weighbridge scales to offer precise weight measurements for cars and their cargo is its principal benefit; it allows enterprises to keep exact inventory control and guarantee adherence to transportation rules.

In addition to being incredibly durable, modern weighbridge systems are accurate even under sensitive environmental situations. Their strong layout guarantees lengthy-time period dependability and coffee upkeep desires; they usually have heavy-obligation metallic platforms and superior load cells. Over time, the gadget’s resilience results in less downtime and fewer preservation expenses.

Modern weighbridge scales’ adaptability is another important advantage. Businesses can select the best configuration for their unique requirements because they can be put above groun, pit-mounte, or portable systems. Organizations can adapt their weighing operations according to operating requirements and available space thanks to this flexibility.

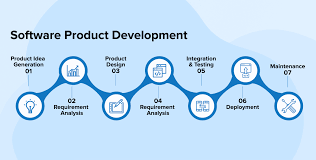

How Weighing Scale Automation Affects

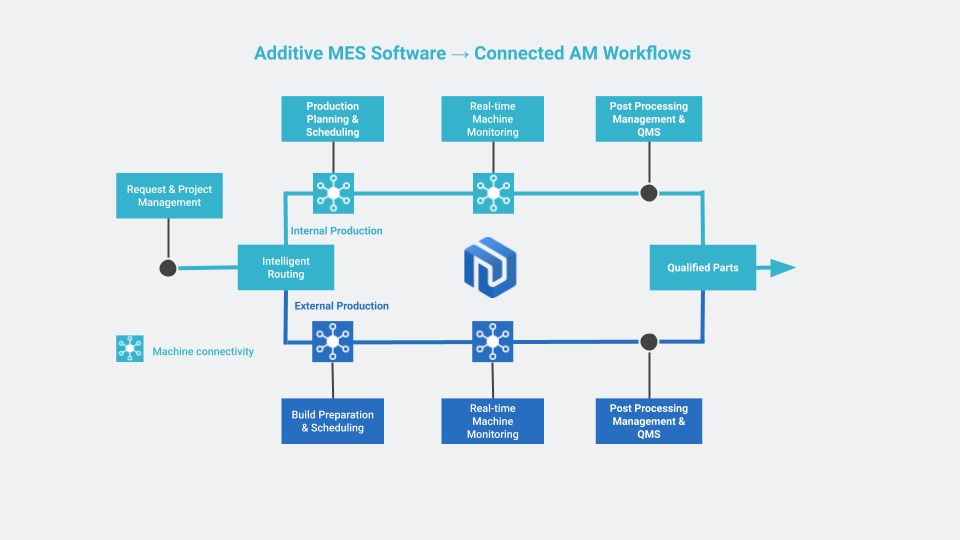

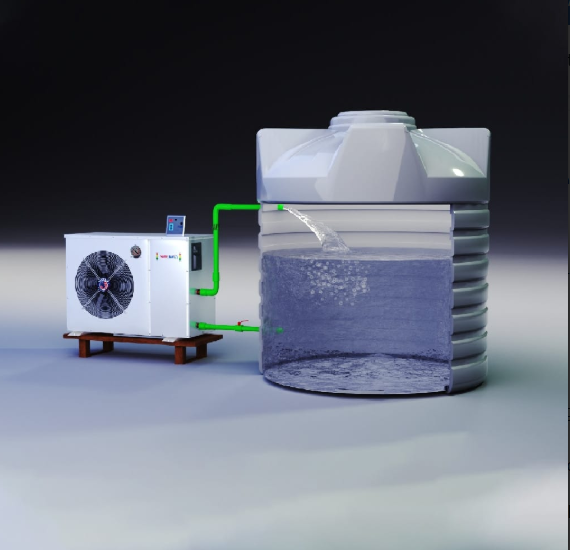

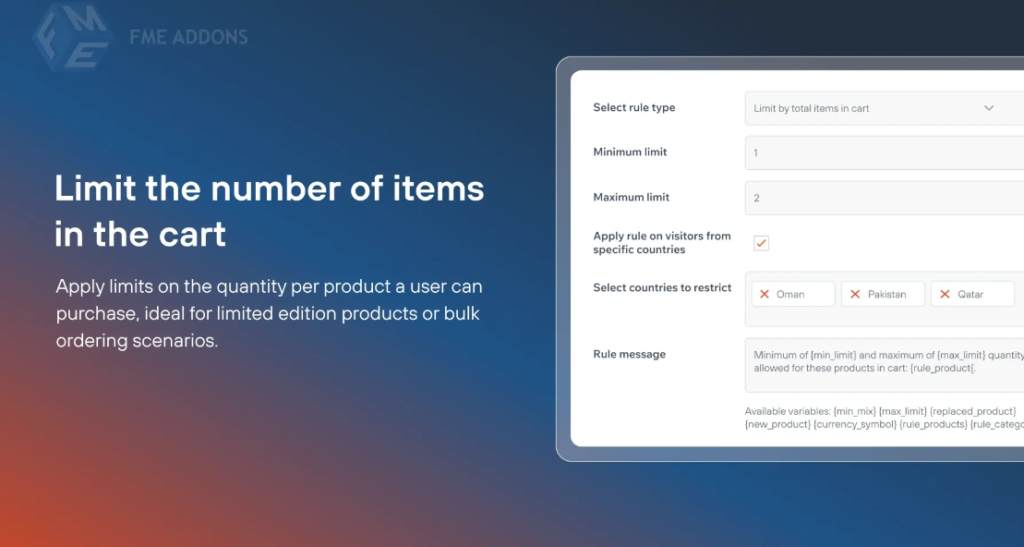

Traditional weighing procedures are now streamline and more effective thanks to automation. Throughput capacity is greatly increase, human error is decrease, and manual data entry is eliminate using automate weighing systems. Data collection and analysis in real-time are made possible by these systems’ smooth integration with current company management software.

By eliminating human participation in normal weighing procedures, weighing scale automation offers one of the biggest benefits. This automation lowers labor expenses and lowers the possibility of mistakes that come with manual data entry. Vehicle information, weight data, and other pertinent information can be automatically recorded by the system and store in a centralize database for convenient access and analysis.

Unattended activities are also made possible by automate systems, which let cars be weighe aroun the clock without the need for employees to be present. For companies who need to accept deliveries outside of usual business hours or that run around the clock, this feature is especially helpful. In addition to lowering operating expenses and increasing efficiency, self-service weighing is made possible by driver terminals and RFID technology.

Better Data Analysis and Management

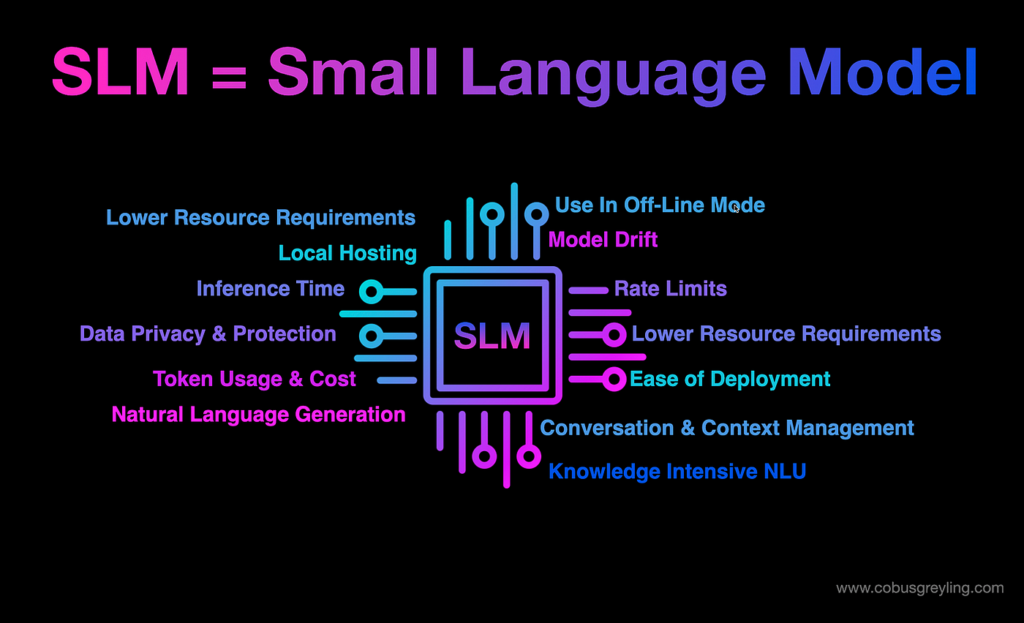

Contemporary weighing systems are excellent at managing data, providing all-inclusive solutions for monitoring, evaluating, and reporting weight-related data. In addition to keeping historical facts and generating comprehensive reviews, those systems can provide insightful statistics for corporation decision-making.

Weighing statistics can be integrate with corporation aid-making plans (ERP) systems to enhance logistical coordination, manufacturing scheduling, and stock control. Access to actual-time records permits managers to unexpectedly make well-knowledgeable choices, enhancing operations and cutting expenses. By automatically growing shipping notes, invoices, and other paperwork, the generation can expedite administrative methods.

Based on past data, advanced analytics capabilities help firms see trends, forecast maintenance requirements, and streamline operations. Organizations may save waste, increase efficiency, and make better strategic decisions with the aid of this data-driven strategy.

Control of Quality and Regulatory Compliance

For regulatory compliance and upholding fine standards, automated weighing structures are vital. To help companies stay out of problems and keep their running licenses, those systems may be set up to meet precise industry standards and regulatory norms.

An audit trail, which might be essential for regulatory compliance and dispute settlement, is supplie using the systems, which hold specific statistics of all weighing transactions. By legal metrology requirements, automated calibration assessments and system diagnostics guarantee that the weighing equipment keeps its accuracy throughout time.

Automated weighing systems make quality control procedures more accurate and reliable. Setting tolerance levels and automatically identifying inconsistencies contributes to waste reduction and product quality maintenance. Industries, where exact weight measurements are essential for product quality and safety, will find this feature especially useful.

Onboard Weighing Systems’ Cost Benefits

Modern weighing structures may have an excessive preliminary value, however, they also offer enormous long-term On Board Weighing System Price savings. These structures have many blessings that assist make certain an awesome go-back on investment.

Labor value financial savings: Automation lowers hard work fees with the aid of casting off the want for data entry and manual weighing sports. Redirecting personnel to higher-value tasks can grow the usual operational effectiveness.

Decrease Error-Related Costs: Automated systems cut down on human error and guide statistics entry, which lowers the costs of errors like misguided billing, inventory inconsistencies, and compliance issues. The precision of automatic structures ensures correct billing for each transaction and prevents profit leaks.

Higher throughput and better useful resource use are the outcomes of quicker weighing approaches and shorter wait times. Additionally, operational performance is improve by the capability to run around the clock without incurring extra staffing fees.

Maintenance and Durability Advantages: Contemporary weighing systems are designed to finalize and need little upkeep. These systems’ advanced diagnostic features lower maintenance costs through predictive maintenance scheduling and help avoid malfunctions.

Ensuring the Future of Your Investment

Weighing devices of today are a wise investment in cutting-edge technology. Because of their scalable architecture, these systems enable companies to grow as their needs change. Since many contemporary systems are modular, adding new features and upgrading them as technology develops is simple.

IoT capabilities and cloud connectivity guarantee that these systems can adjust to new technological advancements. Remotely monitoring and controlling weighing operations offers flexibility and efficiency advantages that will only grow in value as companies continue to digitize their processes.

Conclusion

There are many more advantages to using automated weighing systems and contemporary weighbridge scales than just measuring weight. Comprehensive solutions that guarantee regulatory compliance, boost operational effectiveness, and offer insightful data for business decision-making are provided by these systems. The long-term cost savings and operational benefits make these systems a crucial part of contemporary commercial and industrial operations, despite the very high initial investment. These systems are an essential investment for progressive companies since their capabilities and advantages will only grow as technology advances.

English

English