Understanding the Working of the IGBT Module

Understanding the working principles of IGBT modules as well as their advantages is essential for their effective application in various industries. From High-Power Applications to HVAC systems, power grids and industrial automation, IGBT modules are improving efficiency and performance.

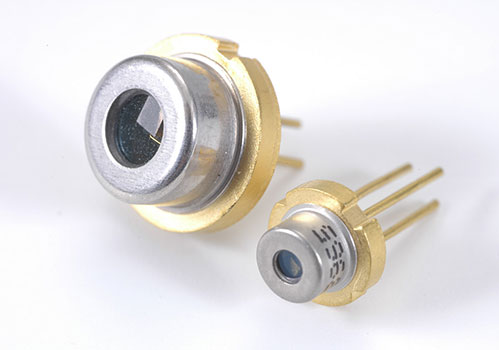

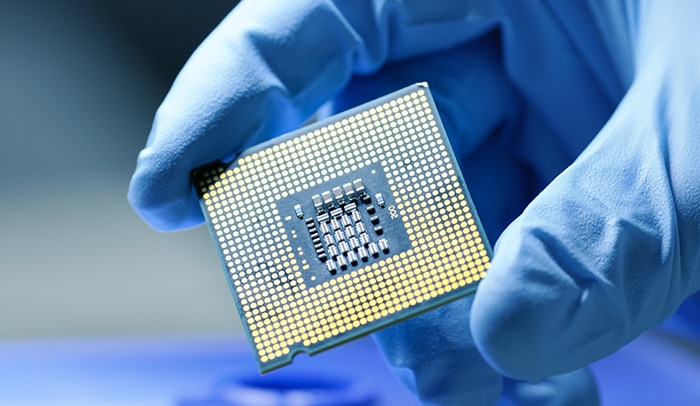

The Insulated Gate Bipolar Transistor (IGBT) is a power electronic device that allows efficient power control and transfer. This transistor combines the input of metal-oxide-semiconductor field-effect transistors (MOSFET) and the output of bipolar junction transistors (BJT), enabling it to run high voltage and high-power applications with minimal power loss.

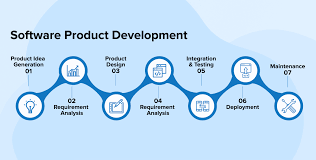

Understanding the Workings of IGBT

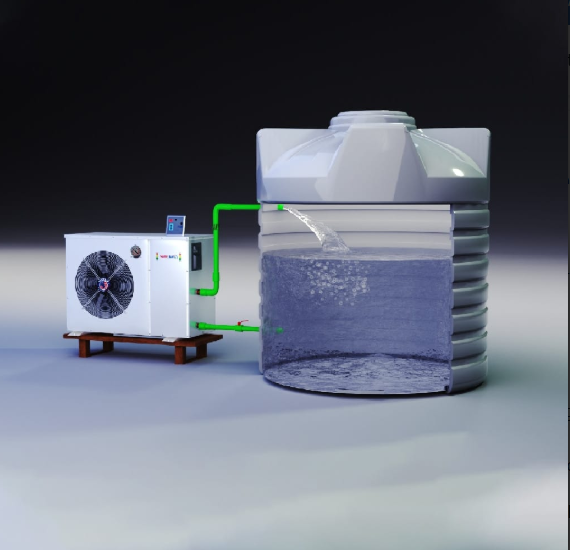

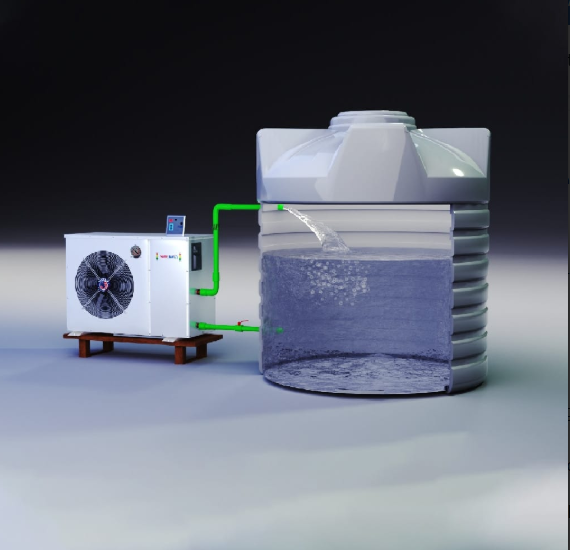

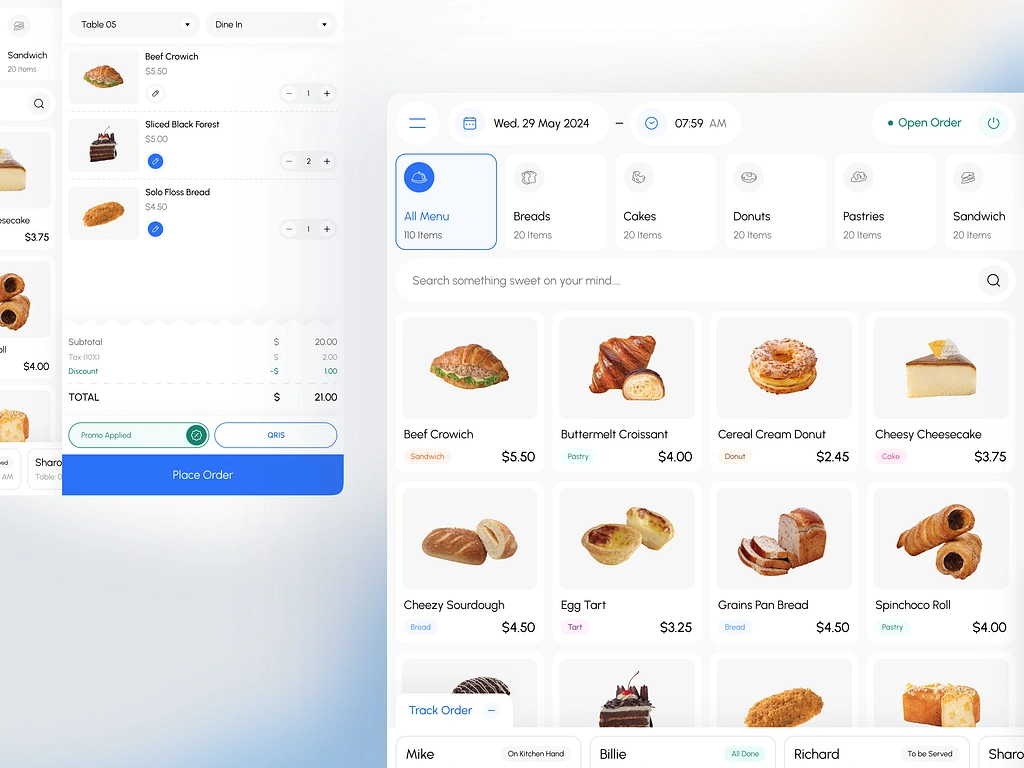

IGBT is valuable in power electronics, especially inverters. IGBT improves the function of semiconductor and acts like an electronic switch. That allows current to flow through based on the voltage applied to its gate terminal. It converting DC into AC used by most household appliances and industrial machinery. Including air conditioners and refrigerators, renewable energy systems, industrial motors, and automotive main motor controllers. As a power device, an IGBT module is composed of several IGBT power semiconductors wrapped into a single package with three terminals attached to different layers.

These terminals – Collector (C), Emitter (E) and Gate (G) serve different roles in controlling the flow of current through the device. The collector and emitter are the terminals from where the current flows into the device, whereas the Gate controls the device and IGBT operation. The collector-emitter connection is established when a positive voltage is applied to the gate thus allowing current to flow through.

Benefits of the IGBT Module

IGBT modules offer several advantages, making them essential for modern power electronics and systems.

Energy Conversion

Unlike traditional BJT modules, IGBT has excellent current handling capabilities. The MOSFET gate structure enables rapid switching between on and off, which helps convert DC to AC. This is particularly ideal for high-frequency applications, like solar inverters that collect direct current from the sunlight and convert it into alternating current to be fed into the power grid.

Better Efficiency

IGBT modules are designed to exhibit low conduction loss during the switching process because of their bipolar nature. It allows them to convert more energy and waste less heat, which is useful in energy-efficient applications like industrial motor drives and renewable energy systems.

Voltage & Current Regulation

In power electronics like motor drives, power supplies and inverters, regulating voltage and current is essential to ensure the system operates efficiently and safely. Without this, these devices can experience voltage fluctuations, draw excessive current and malfunction.IGBT modules can maintain a stable output voltage by adjusting the switching frequency and gate drive signal, ensuring the devices receive the required current.

Thermal Management

Continuous advancements in newer models have helped improve the thermal lifecycle and can support multiple sources. Leading IGBT manufacturers in India, like Mitsubishi Electric India, use carrier cumulative effect. It helps achieve lower power losses even in high-speed industrial applications, thus improving the efficiency of current flow.

The application of IGBT is diverse. They are being widely used in different fields, such as motion control, renewable energy, power supply and more.

English

English