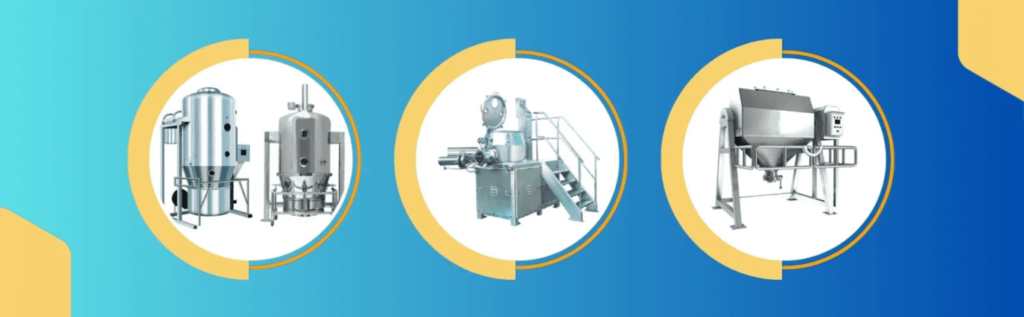

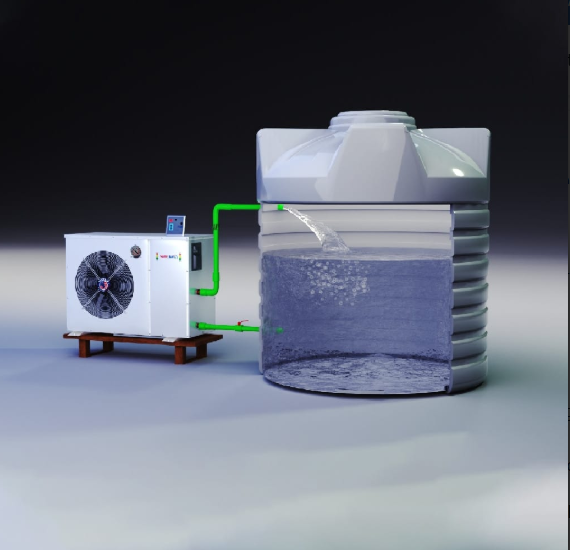

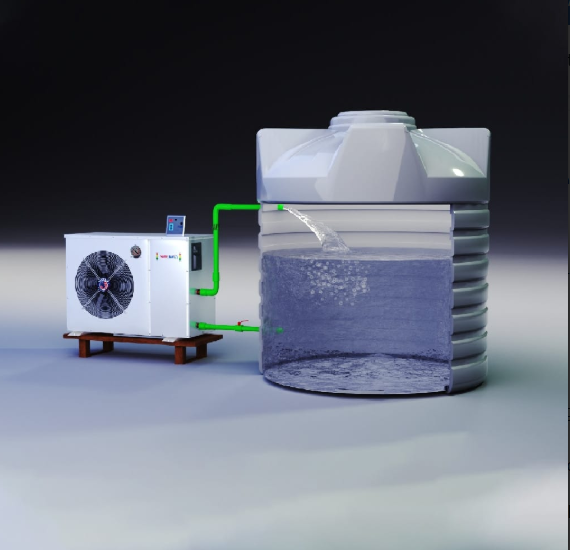

The Amazing Benefits of Tube Expander Machines

The manufacturing industry and construction field among others depend heavily on tube expander machines. The specialized equipment enables proper tube metal expansion along with flaring and shaping processes. Current industrial competition requires appropriate equipment to boost productivity and quality while lowering operational costs. This article demonstrates how modern industrial facilities require tube expanders because their benefits matter irrespective of your investment interests in the technology.

1. Enhanced Productivity

The usage of tube expander devices shortens tube expansion periods leading to higher workplace productivity. Robotics cuts down expansion tasks to levels that exceed human-operated manual working periods thus reducing both duration and workforce requirements. Operators experience reduced physical strain and achieve increased tube processing rates per hour which allows them to perform more important production duties.

2. Superior Precision and Consistency

Achieving accurate, consistent outcomes in each tube processed is the hallmark of high-quality tube expansion. This is where tube expander machines shine since they do away with the variances that come with hand expansion techniques. No matter how many tubes are treated, these machines are designed to apply precisely the right amount of pressure for ideal expansion. Every tube satisfies precise dimensional requirements thanks to the mechanical precision.

3. Improved Worker Safety

Any industrial setting must prioritize safety, and tube expander machines provide notable advancements in this crucial area. These devices eliminate the need for workers to handle potentially sharp metal tubes or use manual instruments that could slip and injure them by automating the expanding process. A lot of contemporary tube expanders have extensive safety features.

4. Cost Efficiency

During its operational period tube expander machines demonstrate superior economic value when considering their initial equipment cost. These robots permit one operator to finish work that needed multiple workers when done manually thus leading to substantial cost reductions. Robotized tube expanders need replacement less often because they function well and maintain consistent quality so businesses face reduced material waste due to incorrect tube expansions.

5. Versatility and Adaptability

Modern tube expander systems enable processing of diverse tube dimensions alongside different materials and expansion degrees because they deliver superior flexibility. Most high-quality models need minimal set-up time for redesigning to handle different sizes of tubes as well as various wall dimensions and expansion ratios.

6. Reduced Material Waste

Reducing waste is a top goal for the economy and the environment in today’s resource-constrained industrial setting. Tube expander machines’ accurate, regulated expansion process makes them excellent at cutting down on material waste. These machines provide precisely the proper amount of force for ideal outcomes, unlike human methods that could lead to over-expansion, uneven flaring, or damaged tubes.

7. Easier Quality Control

When tube expander machines are integrated into production processes, quality assurance becomes much easier. Because machine expansion is accurate and constant, quality control teams may concentrate on spot-checking instead of reviewing every tube because they know that if the machine is calibrated correctly, it will yield consistent results. Measurement devices that can automatically confirm dimensions during processing are integrated into a lot of contemporary tube expanders.

8. Longevity and Durability

Excellent tube expander machines are a wise long-term investment that keeps getting better every year. Usually made of industrial-grade parts, these machines are built to endure the rigors of regular use in harsh conditions. Their sturdy construction guarantees that, aside from regular maintenance, they will continue to function for thousands of expansion cycles.

Conclusion

Tube expander machines prove essential in different industrial fields because they boost efficiency together with accuracy while ensuring safety and reducing Tube expander price. Simplified manufacturing operations are one of multiple benefits that tube expander machines provide while simultaneously reducing expenses and improving product quality.

English

English

Office Clearance for SMEs: Affordable Solutions Businesses

Office Clearance for SMEs: Affordable Solutions Businesses