Reduce Industrial Waste: Practical Steps for Indian Companies

Industrial waste is a growing challenge for companies in India, impacting the environment and depleting valuable resources. However, with proactive strategies and innovative approaches, Indian companies can reduce their waste generation, save money, and contribute to a cleaner, greener India. This guide offers practical steps for businesses looking to minimize waste, aligned with national initiatives and global best practices.

1. Optimize Production Processes (Make in India, Waste Less in India)

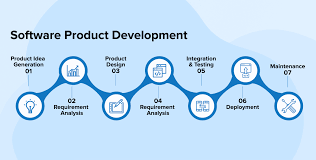

One of the most effective ways to reduce industrial waste is to improve production processes. Implementing strategies such as lean manufacturing can go a long way in waste reduction.

-

Lean Manufacturing: The lean methodology, including tools like Kaizen (continuous improvement) and 5S (Sort, Set in order, Shine, Standardize, Sustain), focuses on reducing waste in various forms—materials, time, motion, and more. Lean principles are particularly beneficial for MSMEs (Micro, Small, and Medium Enterprises) in India, where small improvements can lead to significant reductions in waste.

-

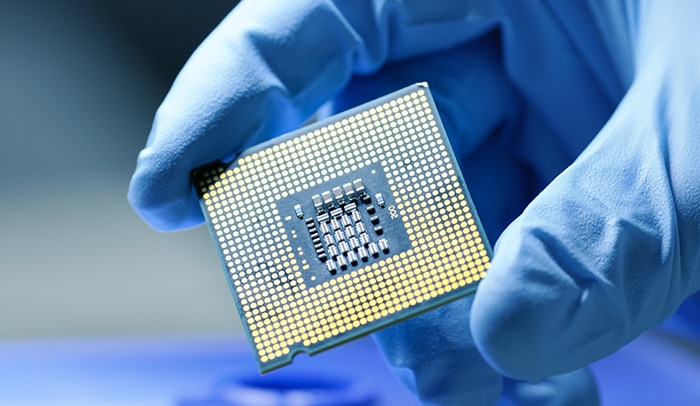

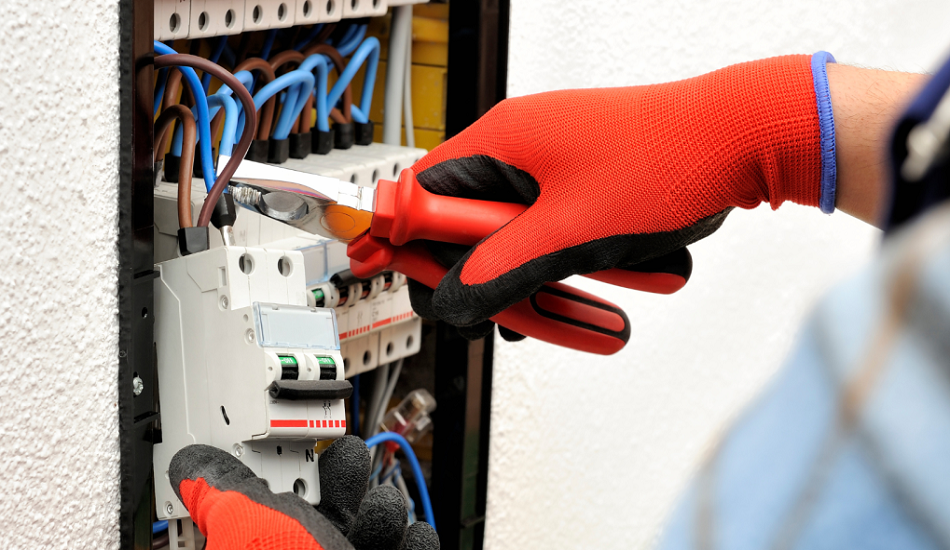

Process Automation: Automating production lines helps improve precision, reduce human error, and minimize material wastage. Automation aligns with India’s “Make in India” initiative, promoting enhanced efficiency and competitiveness within the industrial sector.

-

Energy Efficiency: By optimizing energy use and investing in energy-efficient equipment, companies can lower operational costs while reducing their carbon footprint. In a country like India, where energy consumption is rapidly increasing, reducing energy waste can help businesses stay sustainable.

Practical Action: Start by conducting an audit of your manufacturing process to identify inefficiencies and opportunities for waste reduction.

2. Sustainable Packaging (Vocal for Local, Sustainable Packaging)

Packaging is another significant contributor to industrial waste. Companies can adopt sustainable packaging solutions that reduce their waste footprint and contribute to India’s eco-friendly goals.

-

Minimize Packaging: Simplify product packaging by using minimal material, such as concentrated products that require less packaging or designing reusable packaging that can be used multiple times.

-

Recycled & Biodegradable Materials: Prioritize the use of recycled materials, such as paper and cardboard, and explore biodegradable options like jute, bagasse, or compostable plastics. These materials support the circular economy, reducing dependence on virgin resources.

-

Local Sourcing: By sourcing packaging materials locally, businesses not only reduce transportation-related carbon emissions but also support local businesses. This is in line with India’s “Vocal for Local” campaign, which encourages businesses to support local suppliers.

Practical Action: Evaluate current packaging practices and partner with suppliers who offer sustainable, eco-friendly packaging solutions.

3. Digitalization and Technology (Digital India for Waste Reduction)

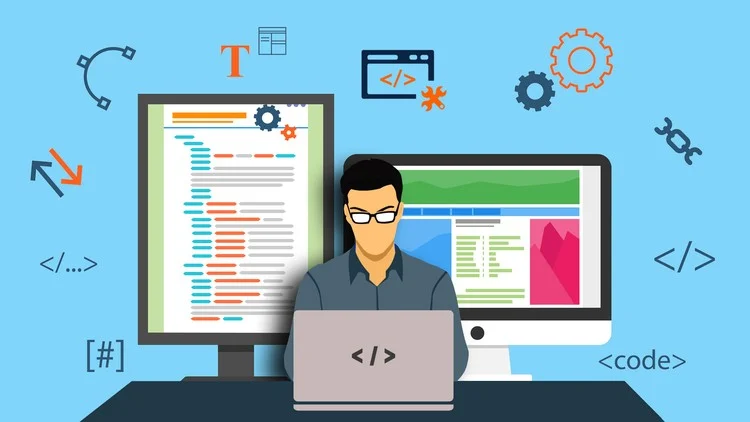

The power of digitalization can help companies track, manage, and reduce industrial waste more effectively.

-

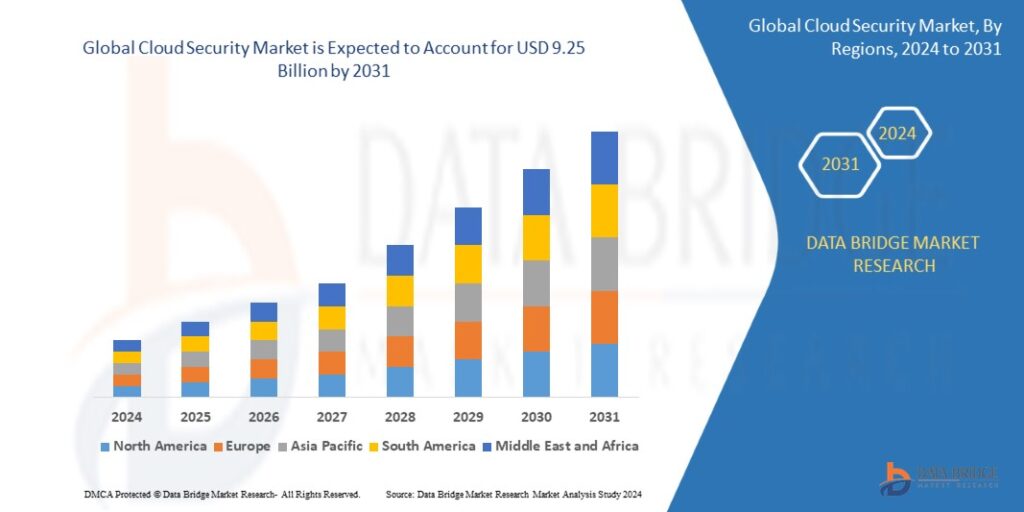

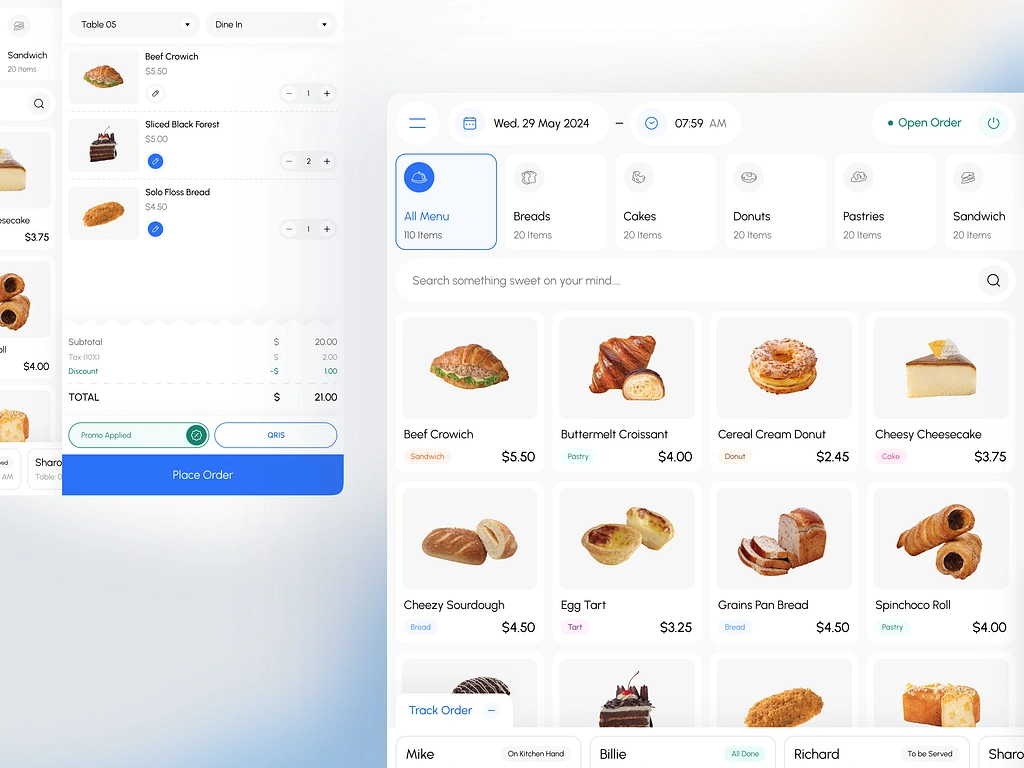

Waste Tracking Systems: Implementing digital waste management systems allows businesses to monitor waste generation, track recycling efforts, and identify problem areas. This data-driven approach can help you make informed decisions for waste reduction.

-

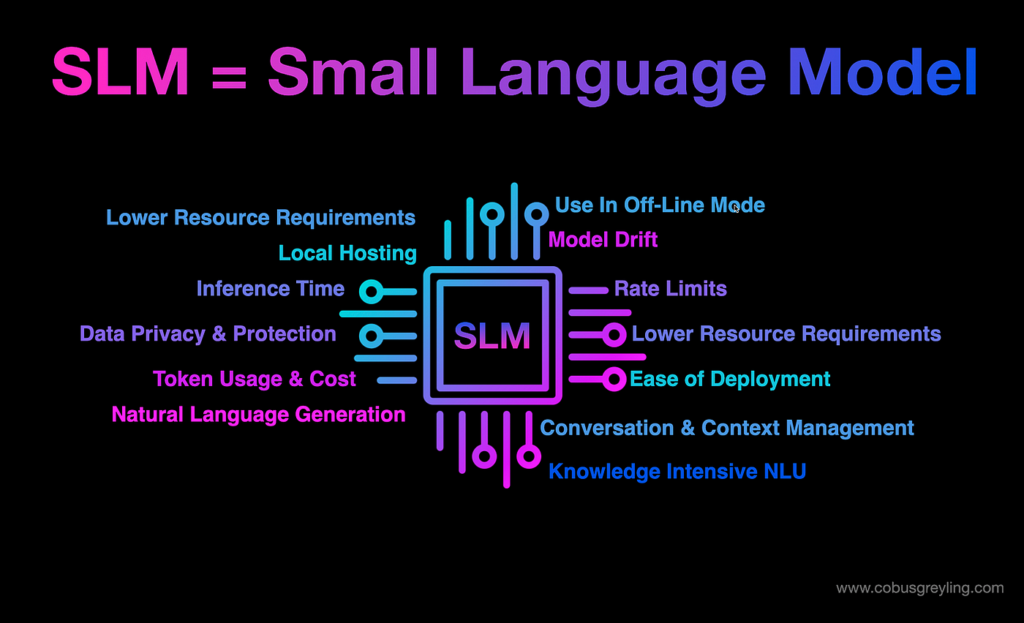

AI-Powered Sorting: Artificial Intelligence (AI) can enhance waste segregation, especially when dealing with complex waste streams. AI-powered systems can separate materials more efficiently, improving recycling rates and ensuring resource recovery.

-

Data Analytics: Leverage data analytics to identify trends in waste generation, predict future waste levels, and optimize waste management strategies. This technology can enable predictive waste management, ensuring companies take action before problems arise.

Practical Action: Invest in software or apps that help manage waste data and integrate AI-based sorting systems to improve recycling efficiency.

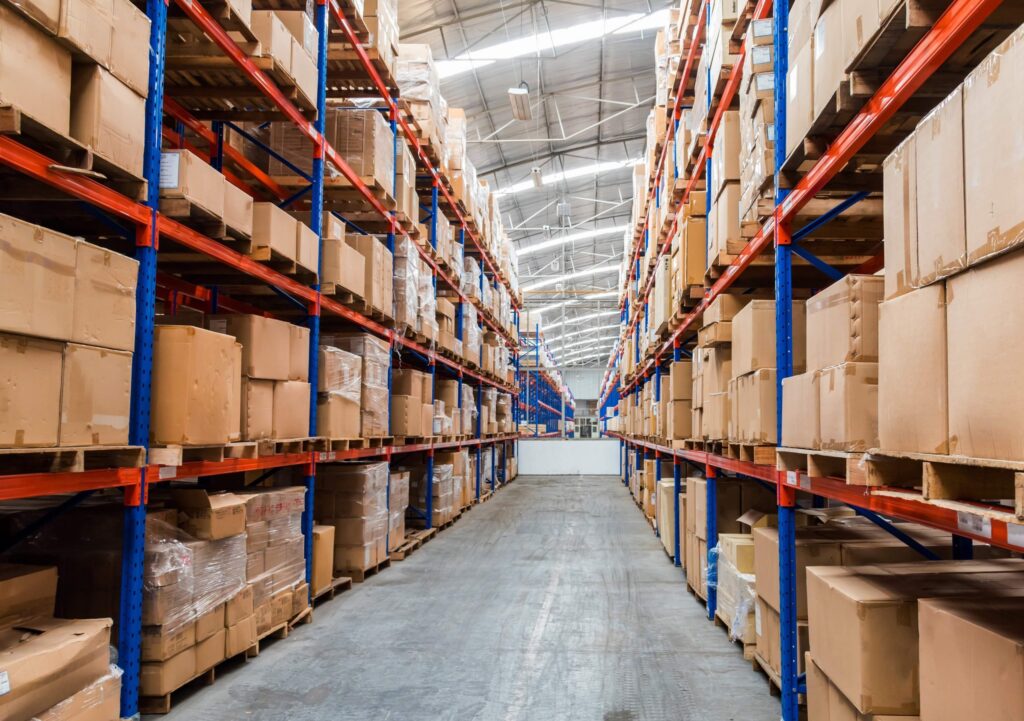

4. Utilize Recycled Materials (Circular Economy in Action)

The circular economy model emphasizes the reuse and recycling of materials, which helps reduce waste generation and the demand for new resources.

-

Incorporating Recyclates: Businesses can reduce their environmental footprint by using recycled materials in their manufacturing processes. For example, using recycled metals or plastics can help conserve natural resources and reduce landfill waste.

-

Waste Exchange Platforms: Use online platforms that connect businesses to exchange waste materials for reuse. This fosters collaboration among industries, encouraging resource sharing and promoting sustainability.

Practical Action: Identify materials in your production process that can be replaced with recycled alternatives and explore waste exchange platforms for surplus waste.

5. Employee Training & Awareness (Skill India for Sustainable Practices)

A culture of sustainability begins with employee education. Proper training is key to ensuring that waste management practices are carried out efficiently throughout the organization.

-

Waste Management Training: Regular training programs on waste segregation, recycling processes, and the environmental impact of waste are essential for creating a workforce that understands the importance of reducing industrial waste.

-

Incentivize Waste Reduction: Recognizing and rewarding employees for their efforts in reducing waste creates a sense of ownership and motivates them to actively participate in sustainability initiatives.

Practical Action: Create a structured training program on waste management, and introduce incentive schemes to encourage employee participation in waste reduction efforts.

6. Set Goals and Track Progress (Measurable Impact)

To achieve meaningful waste reduction, businesses must set clear, measurable goals and track their progress.

-

SMART Goals: Establish Specific, Measurable, Achievable, Relevant, and Time-bound targets for reducing waste. For instance, setting a goal to reduce packaging waste by 10% over the next year can provide clear direction.

-

Regular Monitoring: Continuously monitor progress towards these goals and evaluate the effectiveness of waste management strategies. Regular reviews and updates will help you stay on track.

Practical Action: Implement systems to measure waste generation and regularly publish sustainability reports that reflect the company’s waste reduction achievements.

7. Collaboration and Partnerships (Collective Action)

Waste reduction is a collective effort that requires collaboration between businesses, industry groups, and government organizations.

-

Industry Associations: Join industry associations that focus on waste reduction and sustainability to share best practices and learn from others in the sector.

-

Government Initiatives: Leverage government schemes, incentives, and programs that support waste reduction and recycling projects. India’s Swachh Bharat Abhiyan (Clean India Mission) also encourages businesses to adopt cleaner, greener practices.

-

Extended Producer Responsibility (EPR): Indian regulations mandate that producers take responsibility for their products’ end-of-life management. Complying with EPR regulations ensures that companies manage waste from their products responsibly.

Practical Action: Collaborate with industry partners, adopt government schemes, and ensure compliance with EPR regulations to strengthen your waste management efforts.

8. Certifications and Standards (Recognizing Excellence)

Adopting international standards and obtaining certifications shows a company’s commitment to environmental sustainability.

-

ISO 14001: This certification for environmental management systems helps businesses streamline their waste management practices and demonstrate compliance with global environmental standards.

-

Other Certifications: Companies can explore other certifications related to waste management and recycling, such as ISO 50001 (energy management) or Green Business Certification.

Practical Action: Pursue ISO 14001 and other relevant certifications to showcase your commitment to effective waste management and sustainable practices.

9. Community Engagement (Building a Sustainable Future)

Indian companies can play a significant role in educating the public and encouraging sustainable waste practices.

-

Awareness Campaigns: Companies can partner with local communities and conduct awareness campaigns on the importance of waste reduction, recycling, and sustainable practices.

-

Community Partnerships: Collaborating with NGOs and community groups can help promote waste management initiatives at the grassroots level.

Practical Action: Invest in community outreach programs to promote waste management and involve local communities in sustainability initiatives.

10. Continuous Improvement (The Journey to Zero Waste)

Waste reduction is an ongoing journey. Businesses must stay updated with the latest technologies, regulations, and best practices to continuously improve their waste management systems.

-

Stay Updated: Regularly review emerging technologies, market trends, and regulatory changes to stay ahead in waste management practices.

-

Innovation: Foster a culture of innovation that encourages new ideas and solutions for reducing waste.

Practical Action: Continuously monitor waste reduction initiatives, adopt innovative technologies, and make improvements based on the latest trends in waste management.

Conclusion

Reducing industrial waste is not just an environmental necessity; it is also a business imperative. By implementing the steps outlined above, Indian companies can take control of their waste management processes, cut costs, and contribute to a cleaner, more sustainable future. This proactive approach not only supports national sustainability goals but also enhances the company’s brand image and competitiveness in the marketplace.

Taking steps to reduce industrial waste is good for the planet and good for business. Let’s work together to build a greener, waste-free India!

Also, read other topic: How to Conduct a Trademark Search Before Registering

English

English

Office Clearance for SMEs: Affordable Solutions Businesses

Office Clearance for SMEs: Affordable Solutions Businesses