Protect Welding Systems with Accurate Leak Detection

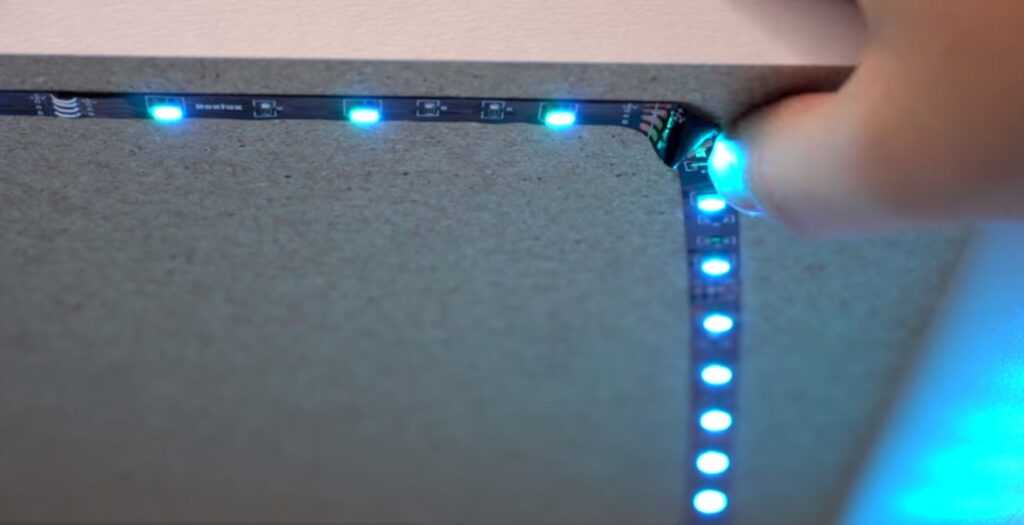

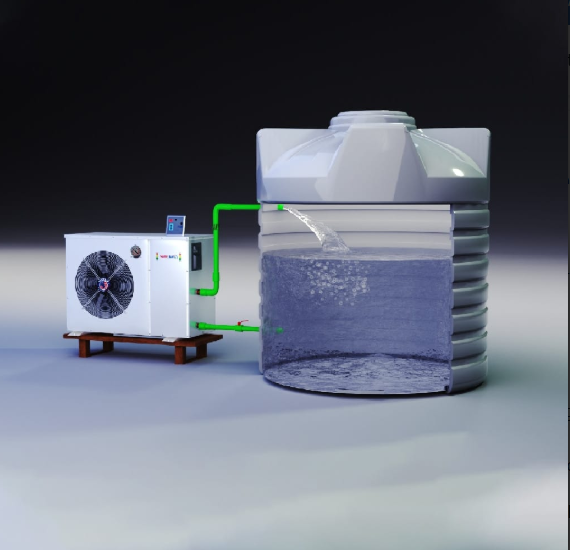

Welding is a process across numerous industries, including automotive and aerospace, construction, and manufacturing. But to keep welding systems in peak performance, there needs to be constant monitoring and preventive maintenance. Perhaps the greatest hazard in welding operations is coolant or gas leaks, which can result in expensive downtime, equipment loss, and safety risks. Accurate leak detection plays a crucial role in ensuring the efficiency and longevity of welding systems.

Proteus Industries Inc. offers advanced solutions for leak detection, including the WeldSaver™ 6 Legacy Series, which helps prevent leaks and enhances welding system reliability.

Why Leak Detection is Crucial for Welding Systems

Leaks in welding systems can cause a range of problems, from minor inefficiencies to severe operational failures. Here’s why accurate leak detection is essential:

1. Prevents Equipment Damage

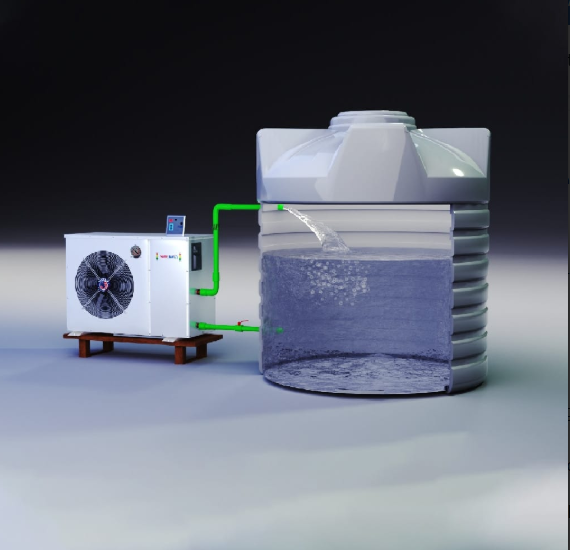

Welding systems use cooling water to maintain optimal temperatures and prevent overheating. If a leak occurs in the coolant lines, it can lead to insufficient cooling, resulting in thermal damage to the welding components. This can reduce the lifespan of the equipment and lead to expensive repairs or replacements.

2. Ensures Safety

Leaks can cause electrical hazards, fire risks, and exposure to harmful gases or chemicals. Welding safety operations involve high temperatures and flammable materials, making it critical to detect and fix leaks before they pose a danger to workers.

3. Reduces Downtime

Unexpected leaks can disrupt production schedules, causing delays and financial losses. By using accurate leak detection, businesses can identify leaks early and perform maintenance before they lead to system failures.

4. Saves Costs

Leaks can lead to wasted coolant, gas, and energy consumption. This unnecessary waste increases operational costs. An efficient leak detection system helps optimize resource usage and lower expenses.

5. Improves Welding Quality

Leaks can cause fluctuations in gas flow, which affects weld quality. Uneven shielding gas coverage can lead to weak welds, porosity, and defects in the final product. Detecting leaks early ensures consistent and high-quality welds.

How Accurate Leak Detection Works

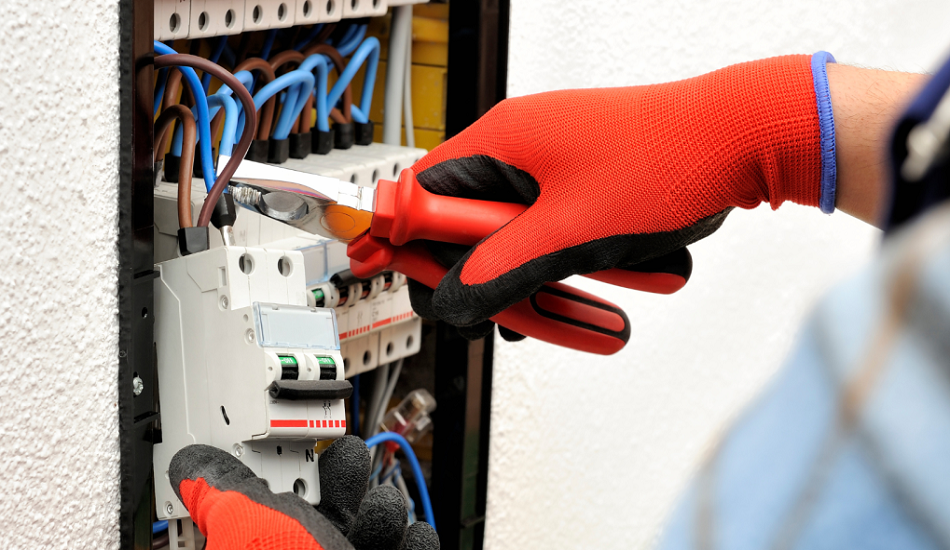

Modern accurate leak detection systems use advanced sensors and monitoring technology to detect even the smallest leaks in welding systems. Here’s how they function:

1. Real-Time Monitoring

Advanced sensors continuously monitor coolant and gas flow, detecting changes in pressure, temperature, or volume that may indicate a leak.

2. Automatic Leak Alerts

The system sends alerts to operators, allowing them to take immediate action before the issue worsens.

3. Precision Sensors

High-precision sensors can identify even tiny leaks that might be missed during manual inspections, ensuring thorough protection of welding systems.

Best Practices for Leak Prevention in Welding Systems

To keep welding systems running smoothly, businesses should follow these best practices for preventing leaks:

1. Regular Inspections

Routine checks on hoses, valves, and connections can help detect early signs of leaks. Look for corrosion, cracks, or moisture buildup around joints and fittings.

2. Use High-Quality Components

Investing in durable, high-quality hoses and fittings reduces the risk of leaks. Cheap materials wear out faster and are more prone to failure.

3. Maintain Optimal Pressure Levels

Excessive pressure can strain welding system components, leading to leaks. Ensure that pressure settings remain within recommended levels.

4. Implement Automated Leak Detection Systems

Using an accurate leak detection system, such as the WeldSaver™ 6 Legacy Series, helps detect leaks early and prevent costly damage.

Advantages of Using WeldSaver™ 6 Legacy Series for Leak Detection

The WeldSaver™ 6 Legacy Series by Proteus Industries Inc. is designed specifically for welding system protection. Here’s why it stands out as a top choice for accurate leak detection:

1. Fast and Reliable Detection

The WeldSaver™ 6 Legacy Series quickly identifies leaks in cooling water systems and prevents overheating issues in welding applications.

2. Automatic Shutoff for Added Safety

The system instantly shuts off the coolant flow when a leak detected, preventing further damage and reducing downtime.

3. Compatibility with Various Welding Systems

It can be integrated into different types of welding operations, ensuring versatility and ease of use.

4. Reduces Maintenance Costs

By detecting leaks early, the WeldSaver™ 6 Legacy Series minimizes the need for costly repairs and extends the lifespan of welding equipment.

5. Enhances Production Efficiency

Preventing unexpected breakdowns and reducing downtime helps businesses maintain smooth and efficient welding operations.

How to Choose the Right Leak Detection System

Selecting the right accurate leak detection system depends on several factors:

- Application Type: Consider whether the system is for manual welding, robotic welding, or automated production lines.

- Detection Sensitivity: Choose a system that can detect small leaks to prevent them from turning into bigger issues.

- Integration Capabilities: Ensure the system is compatible with your existing welding equipment.

- Automation Features: Look for systems that provide real-time alerts and automatic shutoff functions.

- Ease of Use: It is user-friendly interface and simple installation process can make operation smoother for businesses.

Conclusion

Ensuring the protection of welding systems requires proactive measures to detect and prevent leaks. Accurate leak detection helps businesses prevent equipment damage, enhance safety, reduce downtime, and maintain welding quality. Investing in advanced detection solutions like the WeldSaver™ 6 Legacy Series by Proteus Industries Inc. ensures reliable and efficient welding operations.

By implementing best practices and utilizing automated leak detection systems, industries can save money, improve productivity, and it maintain the highest standards of safety and efficiency. For businesses looking to enhance their welding system protection, Proteus Industries Inc. provides the ideal solutions to keep operations running smoothly and securely.

English

English

Office Clearance for SMEs: Affordable Solutions Businesses

Office Clearance for SMEs: Affordable Solutions Businesses