How to Calculate Box Compression Strength of Corrugated Box

Calculating the box compression strength of a corrugated box is important for understanding the durability of stacking and shipping load. Box Compacting Test (BCT) is the most important technique used in the sequence of steps that create the process. The following is a comprehensive guide that helps you determine compression:

Materials and Equipment Needed:

- A box compression tester is a device that generates a compressive force on a box until it breaks.

- Sample Boxes: The corrugated boxes that were tested.

- Recording Equipment: This device, which is often integrated inside the Box Compression Strength Tester, captures the test data.

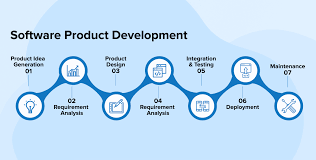

Compression Strength Calculation Steps:

- Prepare the Sample Boxes: Verify that the sample boxes are assembled correctly and in the desired condition. To ensure dependable results, precondition the boxes in a controlled environment if required.

- Configure the Compression Tester Box: Calibrate the Box Compression Tester according to the manufacturer’s instructions. Place the sample box in the middle of the lower plate of the tester.

- Perform the Compression Test: Start the box’s compression strength. As the upper platen begins to descend, the box will be compressed. Do not lose sight of the test. The tester will continue to apply force until the box fails or reaches its maximum box compression strength. The maximum force applied just before a failure is recorded. This is the box’s compression strength.

- Record and analysis data: For each box tested, pay attention to maximum power. Testing multiple boxes – usually 3 to 5 – is a standard process to guarantee and take into account variability. To get an honest measurement, you calculate the average compression force using recorded values.

Factors Affecting the Compression Strength of Box:

- Box dimensions: The height, width, and depth of the box are its dimensions.

- Corrugated board types: Corrugated board comes in single, double, or triple wall varieties.

- Size and type: The flute type and size used in corrugated board.

- Quality of the material: The standard of the paper used to make corrugated boards.

- Environmental factor: Box strength can be affected by temperature and humidity.

Example Calculation:

Suppose that the greatest forces measured following the testing of three boxes were 800 N, 850 N, and 820 N.- Sum of Recorded Forces: 800 N + 850 N + 820 N = 2470 N

- Number of samples: 3

- Average Compression Strength: 2470 N / 3 = 823.33 N

Specifications

- Type: Compression

- Capacity: 1000/2000/3000/4000 kgf (as per customer requirement)

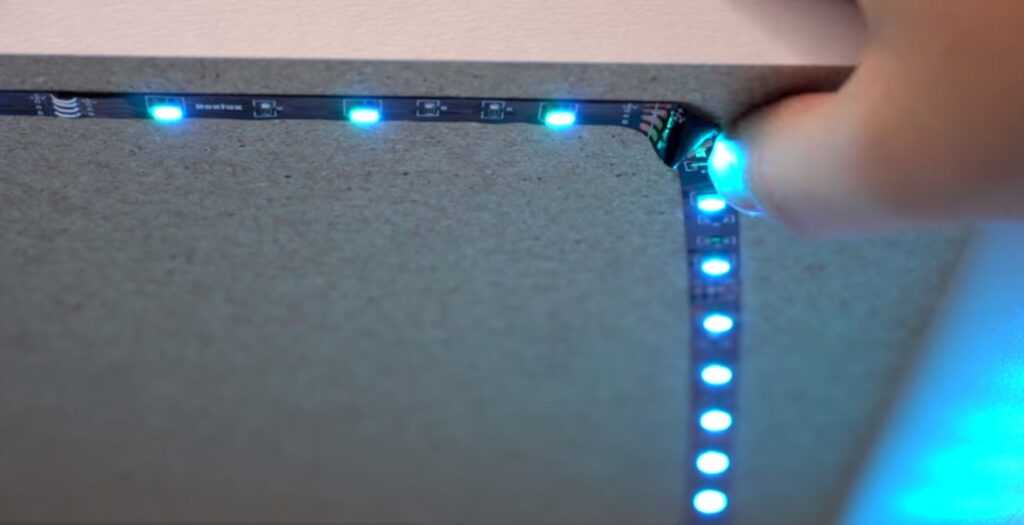

- Display: LED (Digital)

- Accuracy: ± 2% Full scale (with master load).

- At least count: 200 grams

- Shakti: 220V, single phase, 50 Hz

- Test platform size: 600 mm × 600 mm, 800 mm × 800 mm, 1000 mm × 1000 mm, 1000 mm × 1200 mm,

- Test speed: 12.5 ± 2.5 mm/min

- Engine: 1 hp three phases, 1350 rpm

- Standard: ASTM D642, ASTM D4169, Tappi T804, ISO 12048, and JIS Z0212

Features

- Microprocessor-driven display for precise test outcomes

- Extremely precise test findings with consistent compression force

- TARE and peak hold capability

- Over travel safety

- Powerful base plate with a tough construction

- Brilliant LED display

- Feather Touch Controls

- Various platform sizes and load cell capacities are available for the computerized model

- Optional printer facility

English

English

Office Clearance for SMEs: Affordable Solutions Businesses

Office Clearance for SMEs: Affordable Solutions Businesses