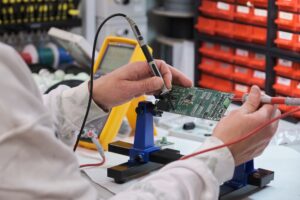

How Electro-Mechanical Assembly Powers Innovation Across Key Industries

Electro mechanical assembly is crucial in modern manufacturing, enabling industries to develop efficient and high-performing systems. Integrating electrical and mechanical components allows companies to create robust products that power industries like aerospace, medical equipment, industrial automation, and telecommunications. This approach optimizes performance, simplifies processes, and enhances reliability across multiple sectors.

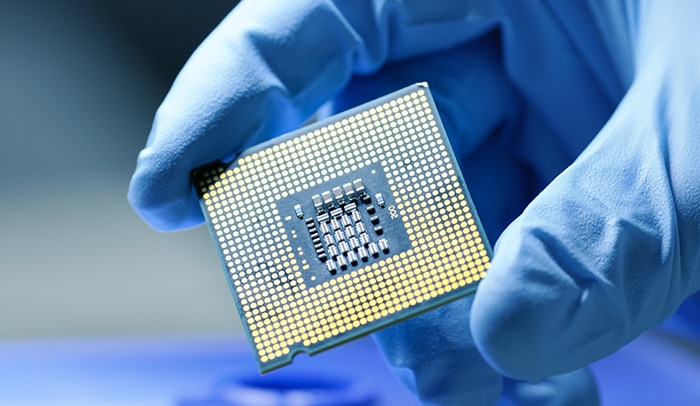

Electro-Mechanical Assembly Explained

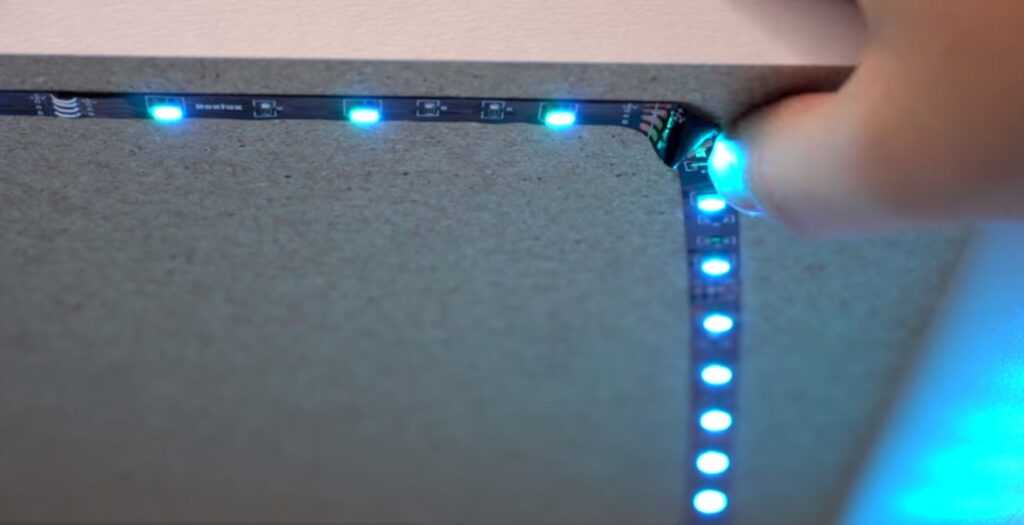

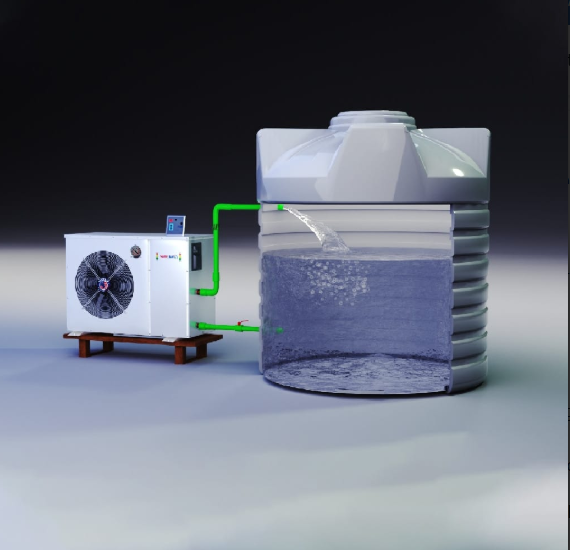

Electro-mechanical assembly is the process of combining electrical and mechanical components into a unified system. This includes circuit boards, motors, sensors, wiring, and enclosures. These assemblies are used in automated production lines, aircraft navigation systems, and advanced medical equipment (among various other applications).

A well-executed electromechanical assembly helps manufacturers ensure that all components work together cohesively, reducing the chances of system failures, increasing durability, and improving efficiency. Businesses and industries that require precision and reliability depend on skilled manufacturers to design, prototype, test, and assemble these complex systems.

Why Electro-Mechanical Assembly Matters

- Enhancing Efficiency and Performance

Integrated electro-mechanical systems streamline operations. For example, industrial automation relies on motors and sensors that are in sync with electronic controls. This reduces the need for human intervention, reduces the occurrence of human error, and increases productivity.

- Reducing System Complexity

A consolidated electro-mechanical assembly eliminates redundant parts, making systems easier to maintain. This results in fewer connection failures and a longer lifespan for equipment.

- Optimizing Space and Weight

Many industries require compact, lightweight solutions. In aerospace, for example, reducing weight improves fuel efficiency and performance. Electro-mechanical assemblies allow for intelligent design choices that save space without compromising quality or functionality.

Industries That Rely on Electro-Mechanical Assembly

- Aerospace and Defense

Aircraft and defense systems require reliable, high-precision components. Flight control systems, radar units, and communication devices all rely on electromechanical assembly to function properly in extreme conditions.

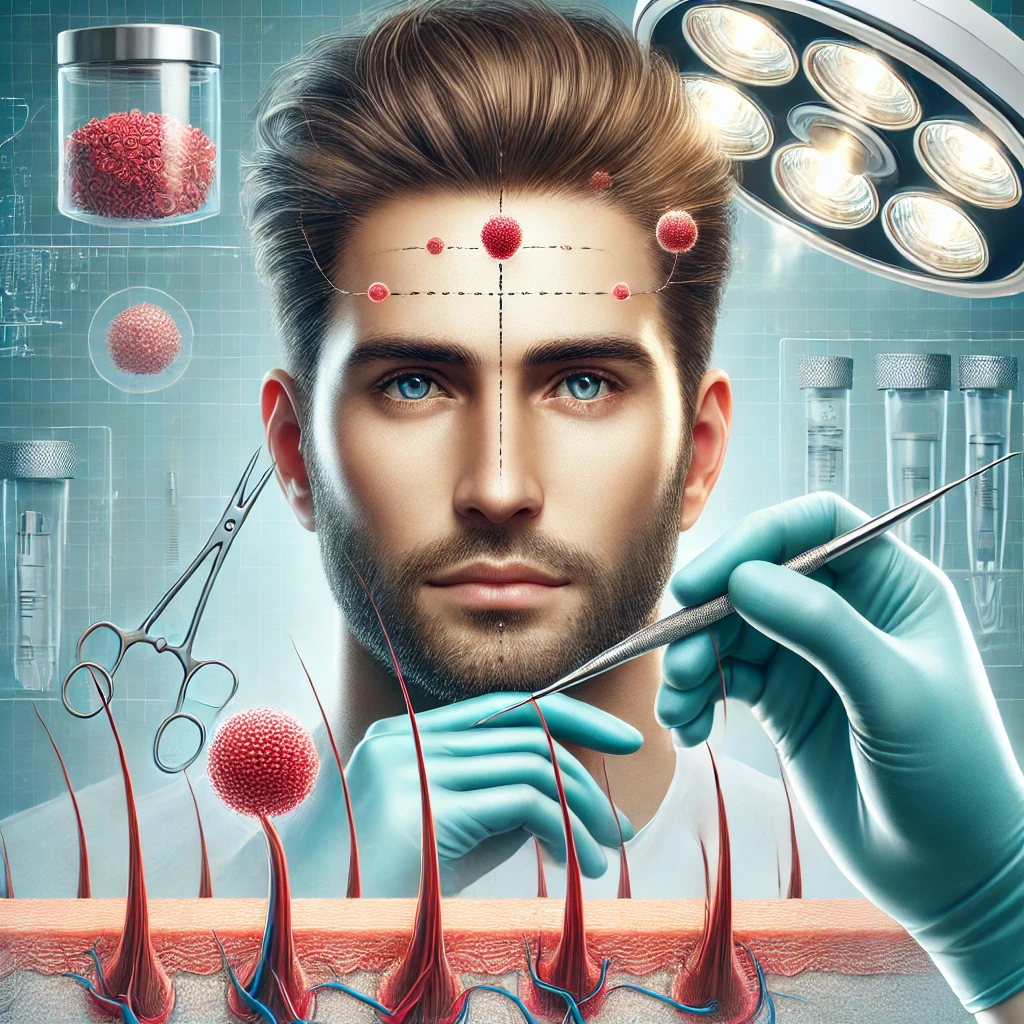

- Medical Technology

The design and manufacturing of medical equipment demand precision and reliability. Surgical robots, imaging systems, and diagnostic devices use electromechanical assemblies to perform highly accurate procedures. Even small design flaws can impact patient safety, meaning quality control is essential.

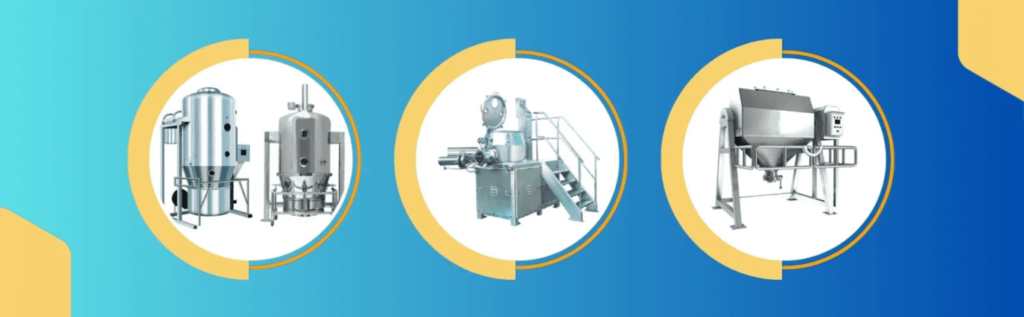

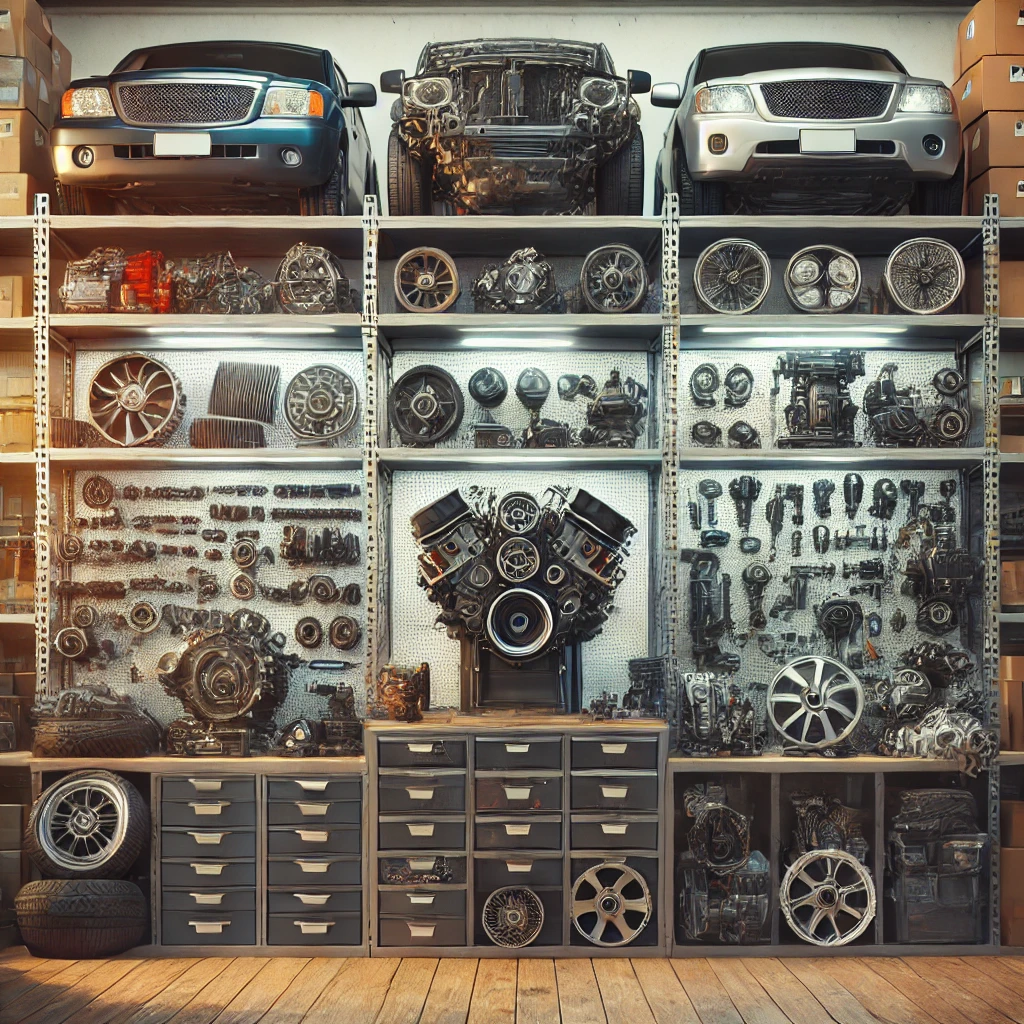

- Industrial Automation

Manufacturing plants use automated machinery to improve production efficiency. These systems include conveyor belts, robotic arms, and automated inspection tools—all powered by electro-mechanical assemblies.

- Telecommunications

Reliable communication systems depend on precise electronic and mechanical integration. High-performance antennas, fiber-optic equipment, and signal processing systems rely on these assemblies for uninterrupted operation.

The Role of an Electronic Assembly Manufacturer

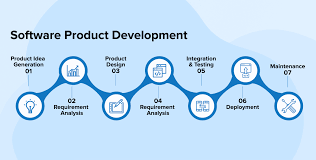

Experienced electronic assembly manufacturers are essential to producing high-quality electro-mechanical systems. Their responsibilities include:

- Design and Engineering

Engineers develop detailed schematics to ensure electrical and mechanical components work together efficiently. This stage focuses on optimizing functionality, cost, and manufacturability.

- Prototyping and Testing

Before mass production, prototypes undergo rigorous testing to detect potential issues. Adjustments are made to improve performance and ensure regulatory compliance.

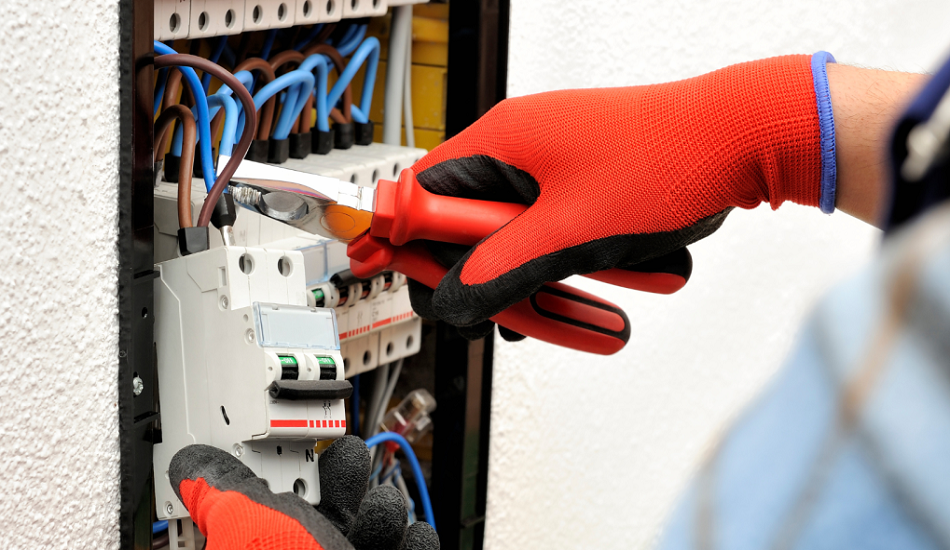

- Manufacturing and Assembly

Production facilities assemble components with precision for consistency across high-volume orders. An electronic assembly manufacturer will use advanced automation and skilled labor to maintain high standards.

- Quality Control and Compliance

Electro-mechanical assemblies undergo extensive testing to ensure they meets industry regulations. This includes stress testing, performance evaluations, and compliance checks for aerospace, medical, and industrial applications.

Choosing the Right Manufacturing Partner

Partnering with the right electronic assembly manufacturer means businesses work with reliable, high-performance electro-mechanical assemblies. The ideal manufacturer provides expertise in design, assembly, testing, and compliance, resulting in products built to last.

A knowledgeable manufacturing partner can help businesses reduce costs, streamline production, and enhance product reliability. Whether developing complex aerospace technology or innovative medical devices, working with a skilled manufacturer is important for consistent quality and precision.

Looking to the Future

Advancements in automation, artificial intelligence, and material science continue to advance electro-mechanical assembly. As industries demand smarter, more efficient solutions, manufacturers must innovate.

Companies that invest in high-quality electromechanical assembly today will be better positioned to meet future demands. By collaborating with experienced electronic assembly manufacturers, businesses can develop products that drive technological progress and maintain industry leadership. Electromechanical assembly is a central feature in modern industry and has enabled breakthroughs in robotics, aerospace, medical technology, and more.

English

English

Office Clearance for SMEs: Affordable Solutions Businesses

Office Clearance for SMEs: Affordable Solutions Businesses