Underground Warning Mesh Tile for Safety and Protection

Ensuring Safety with High-Quality Subsurface Alert Systems

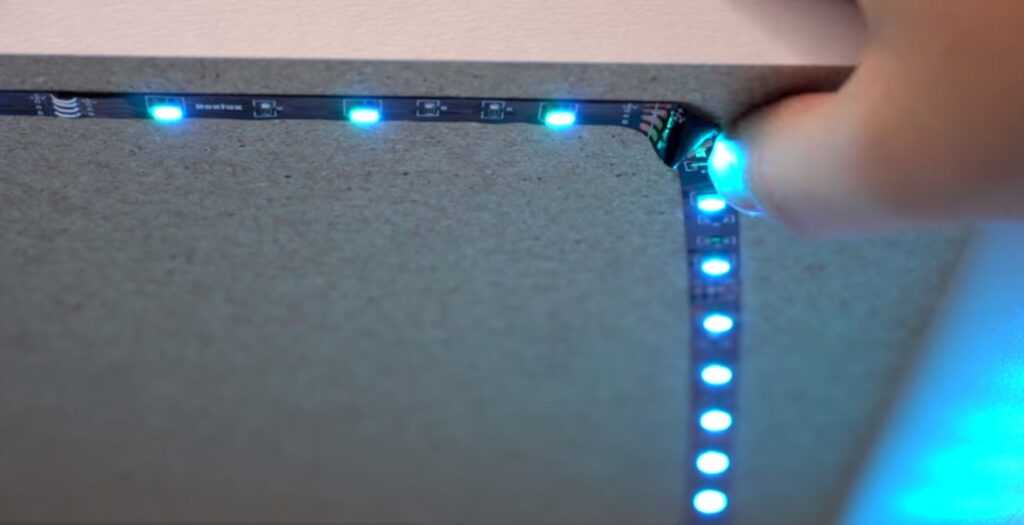

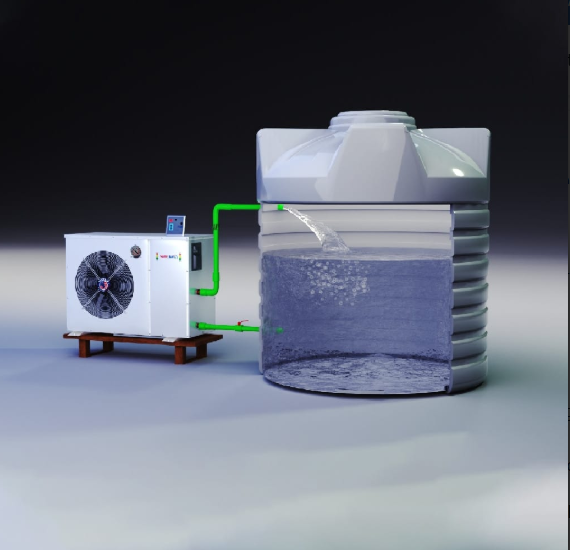

In modern infrastructure development, underground safety measures have become an essential component to prevent accidental damages and ensure compliance with safety regulations. The implementation of specialized alert systems beneath the surface plays a crucial role in protecting buried utilities such as gas pipelines, electrical cables, and water lines. These materials are strategically placed above critical installations to provide an early visual warning during excavation activities. Industries and municipal authorities rely on these safety solutions to minimize risks and maintain operational efficiency in urban and industrial projects. Their bright colors and sturdy construction make them highly effective in preventing accidental damage to underground utilities Underground Warning Mesh Exporters in Ahmedabad increasing construction and infrastructure expansion, these safety measures have gained significant importance in reducing costly repair work and ensuring public safety. The presence of a well-designed alert system beneath the ground can prevent service interruptions and protect essential utilities from unexpected damage.

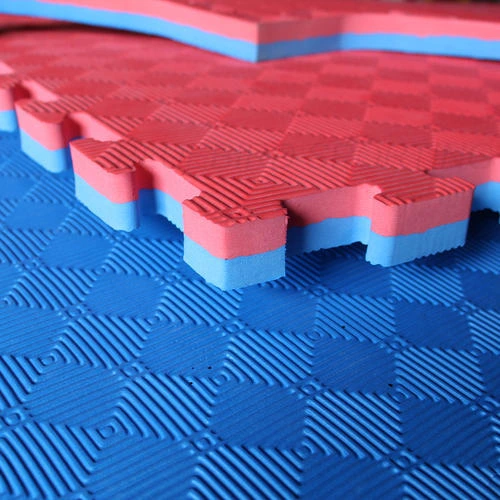

Material Composition and Durability for Long-Term Safety

The effectiveness of underground safety solutions depends on their material composition and durability. These protective layers are typically made from high-density polyethylene (HDPE) or polypropylene, ensuring resistance to environmental factors such as moisture, chemicals, and temperature fluctuations. Their robust structure allows them to withstand pressure from soil movement and external forces without compromising their functionality. Some advanced variants incorporate metallic elements or detectable layers, enabling easy identification using specialized detection equipment. The use of corrosion-resistant materials further enhances their longevity, making them a cost-effective solution for long-term infrastructure safety. Additionally, the flexibility and tensile strength of these protective systems allow them to maintain structural integrity even in harsh conditions. The combination of durability and visibility ensures that these solutions remain effective throughout the lifespan of underground installations. Industries and utility companies benefit from their long-lasting protection, reducing the risk of costly maintenance and repairs.

Applications in Utility and Infrastructure Protection

The use of underground alert systems spans across various sectors, including energy, telecommunications, and municipal services. Their primary application is in the protection of underground gas lines, electrical cables, fiber optic networks, and sewage pipelines. Construction companies and contractors use these materials as a preventive measure to avoid accidental excavation-related damage. Municipal authorities implement these solutions to safeguard water distribution networks and underground drainage systems. They are also widely used in industrial plants to protect sensitive installations that require continuous operational efficiency. The application of these protective layers reduces service disruptions, enhances worker safety, and minimizes legal liabilities for organizations. Their effectiveness in marking underground hazards ensures that excavation crews remain cautious while working on-site. As the demand for secure and reliable underground utility management continues to grow, these protective solutions remain an integral part of urban planning and industrial safety practices.

Importance in Road Construction and Development Projects

Infrastructure development projects, particularly in road construction, require comprehensive safety measures to prevent utility damage during excavation and maintenance work. The installation of high-visibility underground indicators helps ensure that buried pipelines and cables remain protected from accidental interference. These materials serve as an essential tool for engineers and construction workers to identify critical utility lines before beginning any excavation activity. They also play a significant role in preventing costly project delays and repairs caused by accidental utility damage. Government agencies and private developers prioritize the integration of these solutions to enhance road safety and reduce long-term maintenance costs. The strategic placement of underground indicators in road construction projects ensures that transportation networks remain operational without disruptions. Their effectiveness in mitigating risks associated with road excavation contributes to the overall success of infrastructure projects. The proactive use of these safety solutions enhances the durability and reliability of public utilities, reducing potential hazards for both workers and residents.

Innovations in Design and Customization Options

Advancements in manufacturing have led to the development of highly customizable underground safety solutions. Manufacturers offer various design options, including different colors, sizes, and printed warning messages to cater to specific industry requirements. Some products feature multilingual warnings to ensure clear communication in diverse work environments. Additionally, reflective or glow-in-the-dark variants are available for improved visibility in low-light conditions. Advanced production techniques ensure that warning messages remain intact and legible even after prolonged underground exposure. Customization options allow businesses and municipalities to tailor their safety measures to the specific needs of each project. The incorporation of reinforced materials enhances product durability, ensuring that they remain effective in different soil conditions Warning Mesh Manufacturers in India innovations have expanded the usability of underground safety solutions, making them an essential part of modern construction and utility management. Industries benefit from the flexibility and efficiency of these tailored solutions, ensuring compliance with safety standards and reducing operational risks.

Compliance with Safety Standards and Regulations

Ensuring compliance with national and international safety standards is critical when implementing underground protection measures. Various regulatory bodies mandate the use of high-visibility underground indicators in specific applications to minimize excavation-related accidents. Industry guidelines specify the required material strength, color coding, and placement criteria to ensure maximum effectiveness. Many manufacturers adhere to stringent quality control processes to verify that their products meet these safety standards. Organizations that invest in compliant safety solutions demonstrate their commitment to protecting infrastructure, workers, and the public. Non-compliance with safety regulations can result in legal consequences, financial penalties, and operational disruptions. Adhering to industry standards ensures that underground safety measures remain effective in real-world applications. Companies that prioritize compliance benefit from increased operational efficiency and reduced liability risks. Implementing standardized safety solutions enhances the overall reliability and sustainability of underground infrastructure projects.

Economic and Environmental Benefits of Implementing Safety Measures

The use of underground warning systems offers significant economic and environmental benefits for businesses and municipalities. By preventing accidental damage to underground utilities, these solutions reduce repair costs, service interruptions, and liability claims. The long-lasting nature of these protective materials ensures cost-effectiveness in large-scale infrastructure projects. Additionally, many manufacturers focus on producing eco-friendly variants made from recyclable materials, promoting sustainable construction practices. Reducing the risk of environmental contamination due to pipeline leaks or electrical malfunctions further underscores the importance of these safety measures. The economic advantages of investing in proactive safety solutions outweigh the potential costs of repair and legal disputes. Organizations that integrate these measures into their projects benefit from improved risk management and enhanced operational efficiency. By choosing sustainable and high-quality safety materials, businesses contribute to environmental conservation while maintaining industry best practices. The long-term benefits of underground safety solutions make them an invaluable asset in infrastructure development and maintenance.

Conclusion

The implementation of underground safety solutions plays a crucial role in preventing utility damage, enhancing worker safety, and ensuring compliance with industry regulations. These highly visible and durable materials provide an effective means of warning excavation crews about the presence of buried installations. Their applications span across various industries, including construction, telecommunications, and municipal services. Advancements in material technology and customization options have further improved their effectiveness and adaptability. Compliance with safety standards ensures that businesses and government agencies prioritize infrastructure protection while minimizing operational risks. Additionally, the economic and environmental benefits of Warning Mat Manufacturers in Ahmedabad solutions highlight their long-term value in infrastructure development. By integrating reliable underground safety measures, organizations can prevent costly accidents, reduce liabilities, and contribute to sustainable urban planning. As the demand for secure and efficient utility management grows, these solutions remain an essential component of modern safety practices.

Frequently Asked Questions

How do underground safety markers help prevent excavation accidents?

These high-visibility materials serve as an early warning system, alerting excavation crews about the presence of buried utilities. Their placement helps prevent accidental damage to pipelines, electrical cables, and fiber optic networks, ensuring safety and reducing costly repair work.

Are these materials suitable for different soil conditions?

Yes, they are designed to withstand various soil conditions, including moisture-rich environments, rocky terrain, and extreme temperatures. Their durable construction ensures long-term effectiveness in different geographical regions and infrastructure projects.

Can these protective layers be customized for specific projects?

Yes, manufacturers offer customization options such as different colors, printed warning messages, and multilingual text. Customization enhances communication and ensures that safety messages are clearly understood by workers across diverse locations.

What are the key factors to consider when choosing underground safety materials?

Businesses should consider factors such as durability, compliance with safety regulations, visibility, and ease of installation. Selecting high-quality materials ensures long-term protection and reduces the risk of accidental utility damage during excavation work.

English

English

Office Clearance for SMEs: Affordable Solutions Businesses

Office Clearance for SMEs: Affordable Solutions Businesses