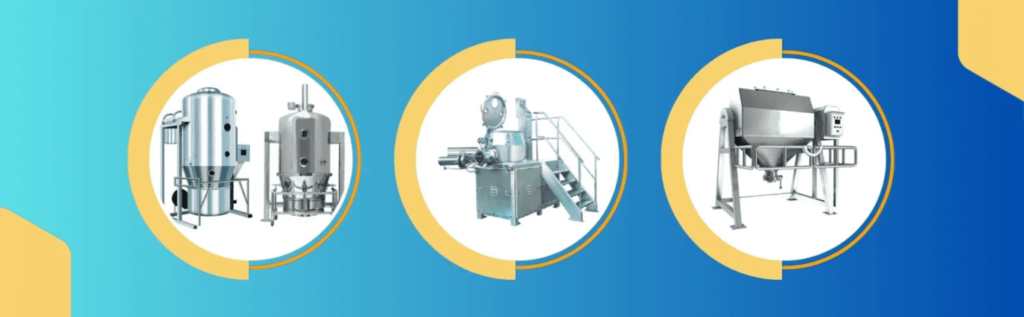

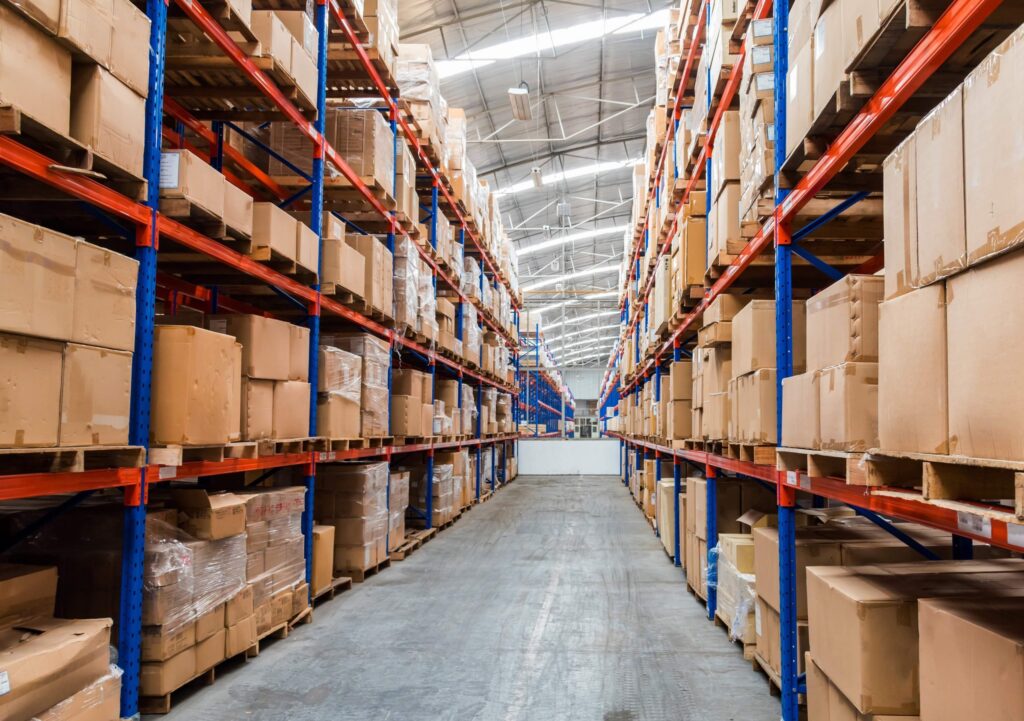

In industries ranging from manufacturing to logistics, conveyor belts are the backbone of efficient operations. These systems keep goods moving seamlessly, but like any machinery, they require regular care to perform at their best. Proper Conveyor Belt Maintenance can extend the lifespan of your equipment, reduce downtime, and prevent costly repairs. To help you keep your conveyor belts in top shape, here’s a guide to the essential do’s and don’ts.

The Do’s of Conveyor Belt Maintenance

- Inspect Regularly

Routine inspections are critical for catching small issues before they escalate. Check for signs of wear, misalignment, or damage to the belt surface, rollers, and pulleys. A consistent inspection schedule ensures your system stays reliable. - Keep It Clean

Debris, dust, and spills can accumulate on the belt and its components, leading to premature wear or malfunctions. Use appropriate cleaning methods—such as brushes or compressed air—to keep the system free of buildup without damaging the belt material. - Lubricate Moving Parts

Bearings, rollers, and other moving components need proper lubrication to reduce friction and prevent overheating. Follow the manufacturer’s guidelines on the type and frequency of lubrication to maintain smooth operation. - Tension the Belt Properly

A belt that’s too loose or too tight can cause slipping, tracking issues, or excessive strain on the system. Adjust the tension according to the manufacturer’s specifications to ensure optimal performance. - Train Your Team

Equip your staff with the knowledge to operate and maintain the conveyor system correctly. Proper training reduces the risk of human error, which is a common cause of belt damage.

The Don’ts of Conveyor Belt Maintenance

- Don’t Ignore Warning Signs

Unusual noises, vibrations, or belt slippage are red flags that something’s wrong. Ignoring these symptoms can lead to major breakdowns. Address problems as soon as they appear to avoid bigger headaches later. - Don’t Overload the System

Every conveyor belt has a weight capacity. Exceeding it can strain the belt, motor, and other components, leading to tears or mechanical failure. Stick to the recommended load limits at all times. - Don’t Use Harsh Chemicals

While cleaning is essential, avoid aggressive solvents or chemicals that could degrade the belt material. Stick to mild, manufacturer-approved cleaning agents to protect the system’s integrity. - Don’t Skip Professional Servicing

DIY maintenance is great for day-to-day care, but complex repairs or adjustments should be left to experts. Skipping professional servicing can result in improper fixes that shorten the belt’s lifespan. - Don’t Neglect Documentation

Failing to keep a maintenance log can make it hard to track issues or predict when parts need replacing. Record all inspections, repairs, and replacements to stay ahead of potential problems.

Why Conveyor Belt Maintenance Matters

Investing time and effort in Conveyor Belt Maintenance isn’t just about fixing what’s broken—it’s about preventing issues in the first place. A well-maintained conveyor system boosts productivity, enhances safety, and saves money by avoiding unexpected downtime. Whether you’re running a small operation or a large-scale facility, following these do’s and don’ts will keep your conveyor belts rolling smoothly for years to come.

Take charge of your maintenance routine today, and your conveyor system will thank you with consistent, trouble-free performance!

English

English

Office Clearance for SMEs: Affordable Solutions Businesses

Office Clearance for SMEs: Affordable Solutions Businesses