Tips to Choose the Best Impact Socket Suppliers

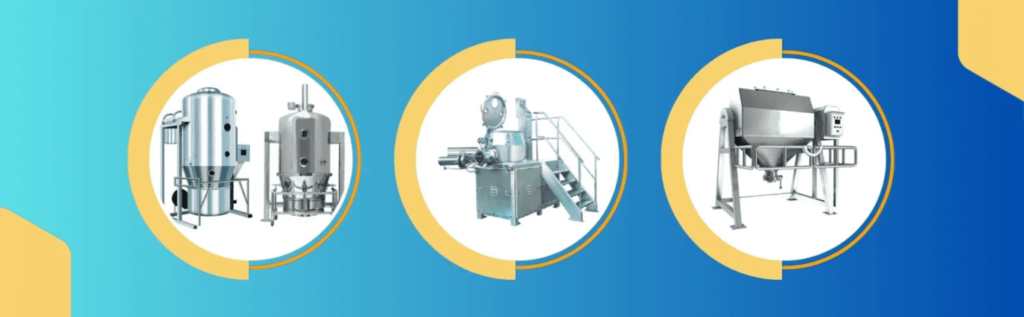

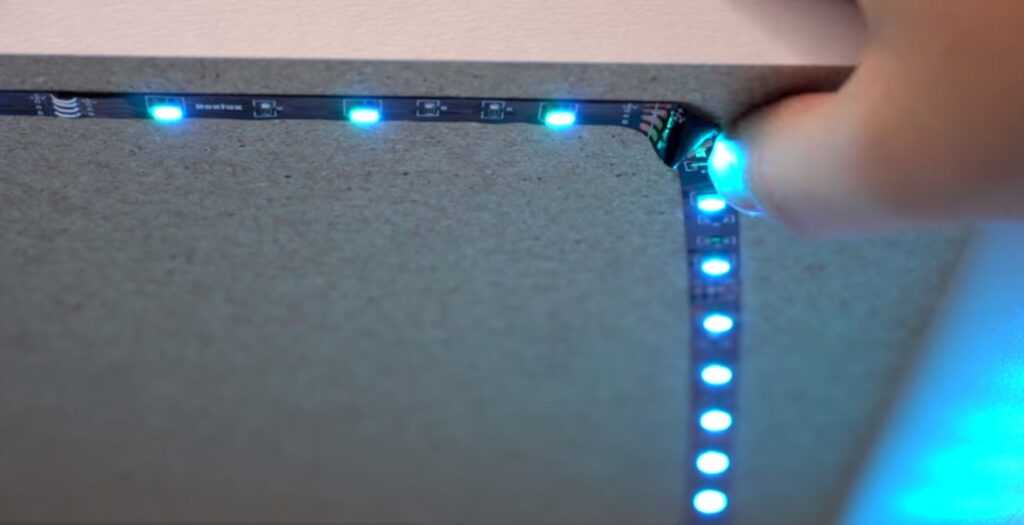

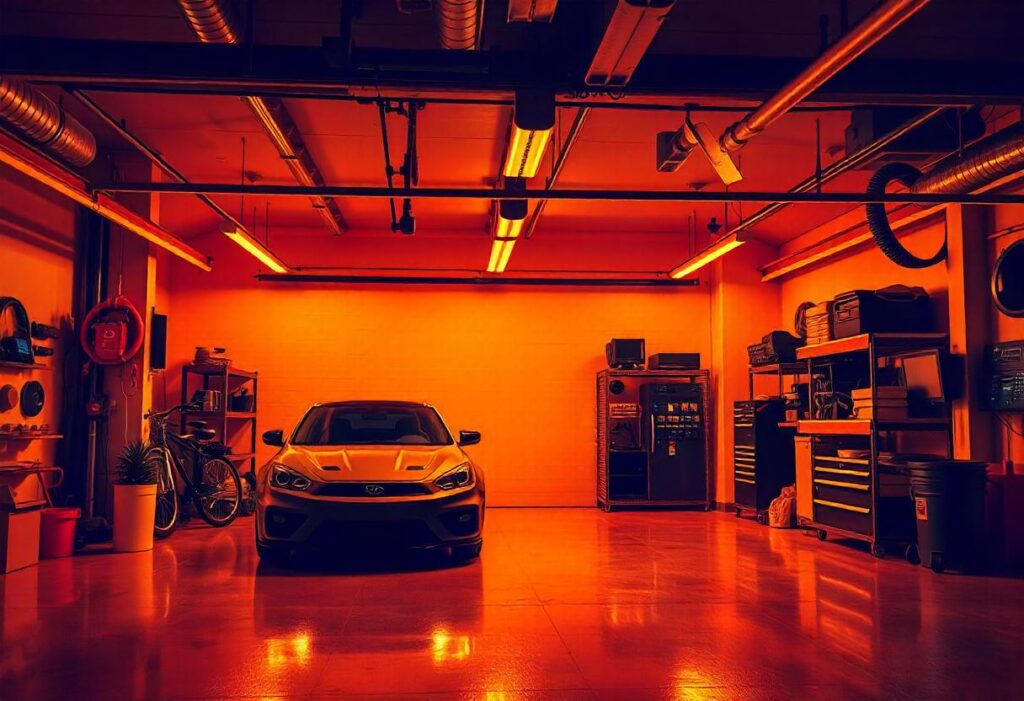

Having trustworthy tools is essential for heavy-duty mechanical operations. Impact sockets are among these crucial instruments, which must endure extreme pressure and torque. Locating reliable impact socket suppliers might mean the difference between expensive failures and successful projects. The ideal supplier offers more than simply goods; they also offer value, dependability, and consistency to maintain your business operations efficiently. Whether you’re in charge of construction projects, garage management, or industrial maintenance, these five useful suggestions can help you choose providers who actually deliver.

1.Quality Over Price

However, sacrificing quality when it comes to impact sockets might have disastrous results. Inexpensive sockets frequently use subpar metals that deteriorate rapidly or shatter under stress. When a budget socket broke during a crucial repair job, resulting in delays and extra costs, you had to learn this lesson the hard way.

2.Industry Certifications Matter

Certifications from the industry are important markers of quality and dependability when choosing impact socket providers. Reputable producers make sure their goods fulfill strict performance and safety criteria by adhering to standards such as ANSI, ISO, and DIN regulations. These certificates are more than simply documents; they are the result of stringent testing procedures that confirm endurance in harsh environments. Quality control systems are usually used throughout the production process by certified suppliers, which leads to consistent product performance.

3.Product Range Variety

The top vendors are aware that there is no one-size-fits-all solution for impact sockets. Different drive sizes, depths, and socket types are probably needed for your applications. You can avoid the headache of managing several vendors by working with a supplier who offers a wide selection. Our work was much more productive during a recent plant maintenance downtime since you had access to a full set from a single source. Seek vendors who provide a range of sizes and configurations of normal, deep, thin-wall, and custom sockets.

4.Warranty and Support

In the area of business, it is inevitable that tools may break. How they respond to these circumstances is what distinguishes great suppliers from average ones. Robust warranty policies demonstrate a supplier’s faith in their goods and dedication to client happiness. Beyond the typical warranty duration, take into account the supplier’s track record of keeping their promises without adding undue bureaucracy.

5.Stock Availability Consistency

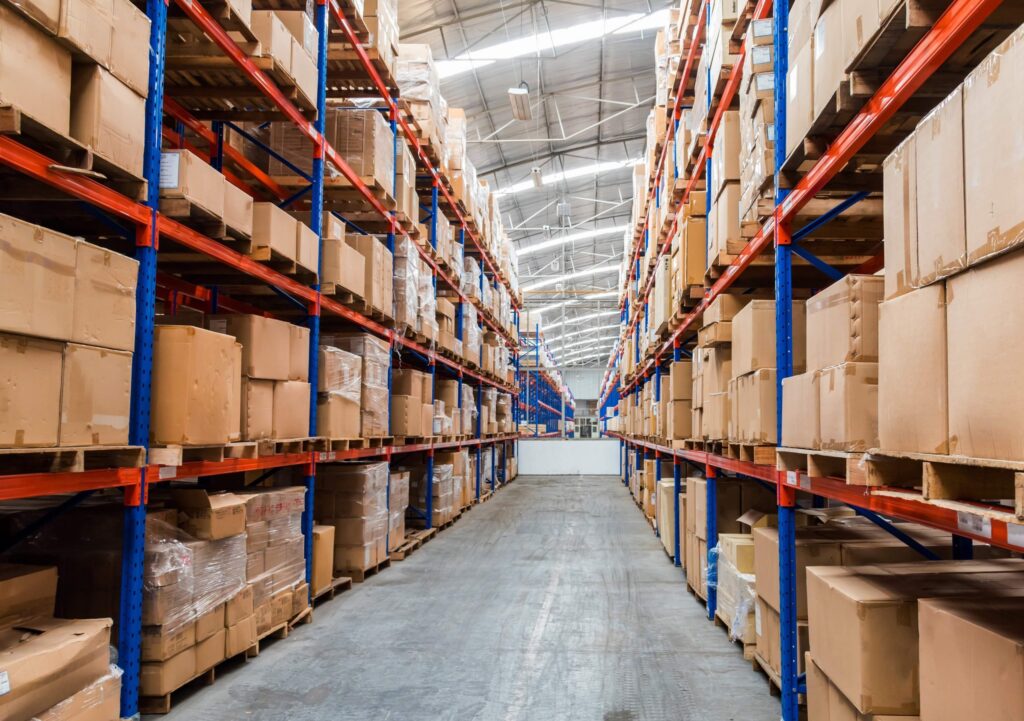

Waiting for backordered tools is the fastest way to ruin a project. Reputable vendors have steady stock levels of their best-selling products. They organize their activities in accordance with their understanding of the urgency that is frequently connected to tool requirements. Ask prospective suppliers about their usual lead times and stock management procedures.

Conclusion

It’s important to consider factors other than price and product features when choosing an impact socket manufacturer. The top manufacturers become invaluable collaborators in your work, offering you peace of mind in addition to tools. You may build connections with suppliers who truly understand your demands by taking into account elements like material quality, certification standards, product diversity, customer support, and logistical reliability. Because of their continuously dependable performance, the proper manufacturer helps you save time, avoid irritation, and preserve your professional reputation in addition to saving you money.

English

English

Office Clearance for SMEs: Affordable Solutions Businesses

Office Clearance for SMEs: Affordable Solutions Businesses