How CNC Machining Service Can Improve Your Production Efficiency

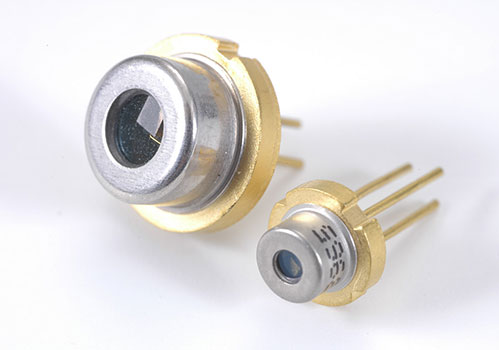

CNC Machining Service plays a crucial role in modern manufacturing by offering unparalleled precision and consistency. Unlike manual machining, which relies on human skill and is susceptible to errors, CNC machines operate with computer-controlled accuracy, ensuring each part is produced to exact specifications. This level of precision is particularly beneficial for industries requiring intricate designs and tight tolerances, such as aerospace, automotive, and medical device manufacturing. By eliminating variations caused by human error, CNC machining enhances product reliability and reduces the need for rework, ultimately improving production efficiency.

Another advantage of CNC machining is its ability to replicate complex designs consistently across large production runs. Once a digital design is programmed into the system, the machine can produce identical parts with minimal deviation. This repeatability ensures that manufacturers can maintain high-quality standards across all batches, reducing material waste and increasing overall efficiency. The precision of CNC machining also reduces the likelihood of defective parts, leading to cost savings and improved customer satisfaction.

Speeding Up Production Processes

One of the most significant ways CNC Machining Service improves production efficiency is by accelerating the manufacturing process. Traditional machining techniques often require extensive manual setup and adjustments, which can be time-consuming. In contrast, CNC machines can rapidly switch between tasks with minimal downtime. Automated tool changes, efficient cutting speeds, and simultaneous multi-axis machining allow CNC machines to complete complex jobs faster than traditional methods.

Additionally, CNC machining minimizes production bottlenecks by enabling continuous operation. Unlike manual machining, which requires operators to be present for each step, CNC machines can run unattended for extended periods, including overnight shifts. This ability to operate around the clock significantly boosts output rates, allowing manufacturers to meet tight deadlines and scale their production capabilities without increasing labor costs.

Reducing Material Waste and Cost Savings

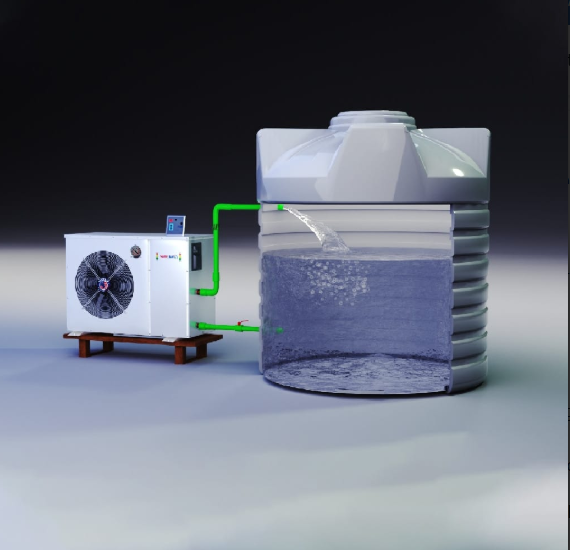

CNC Machining Service optimizes material usage, reducing waste and lowering production costs. Traditional machining methods often result in excessive material wastage due to imprecise cutting and errors. However, CNC machines use advanced programming and simulation software to determine the most efficient cutting paths, minimizing scrap and maximizing raw material utilization. This precision not only reduces costs associated with wasted materials but also contributes to sustainable manufacturing practices.

Furthermore, CNC machining reduces the need for manual labor, which can be expensive and time-consuming. By automating machining processes, manufacturers can decrease dependency on skilled labor while improving productivity. This cost-effective approach allows businesses to reinvest savings into research, development, and expansion, ultimately leading to long-term growth and competitiveness in the market.

Increasing Flexibility and Customization

Another key benefit of CNC Machining Service is its ability to offer flexibility and customization without compromising efficiency. Traditional manufacturing techniques often require dedicated molds or tooling, which can be expensive and time-consuming to modify. CNC machining, on the other hand, allows manufacturers to quickly adjust designs, accommodate custom orders, and produce small or large batches with equal efficiency.

This adaptability is particularly valuable for industries that require rapid prototyping and product iterations. Engineers and designers can quickly test new designs, make necessary modifications, and move to full-scale production with minimal delay. This agility enables businesses to respond to market demands more effectively, providing customers with high-quality, customized products while maintaining efficient production workflows.

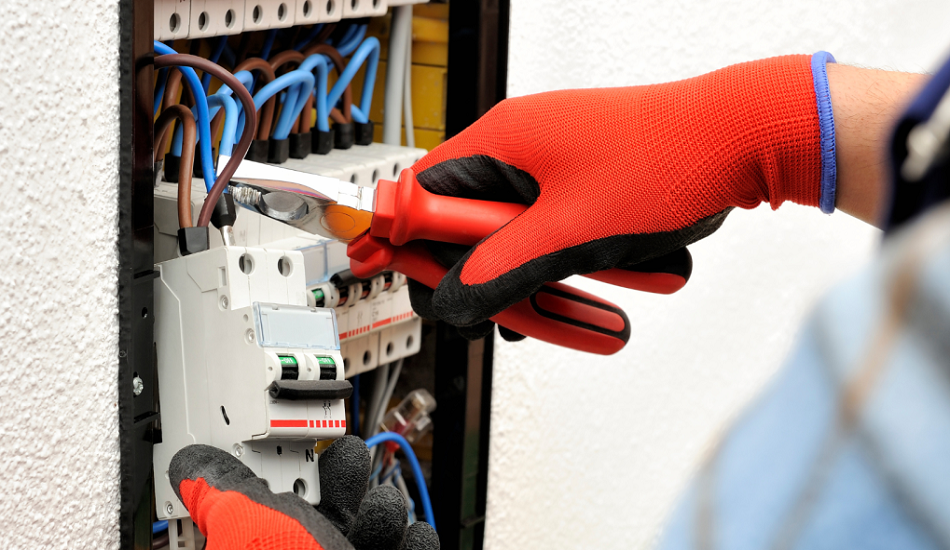

Enhancing Workplace Safety and Reducing Downtime

Workplace safety is a critical factor in production efficiency, and CNC Machining Service significantly improves safety standards. Traditional machining methods often involve direct human interaction with cutting tools, increasing the risk of accidents and injuries. CNC machines, however, operate with minimal human intervention, reducing exposure to hazardous conditions and improving overall workplace safety.

Additionally, CNC machines require less maintenance and experience fewer breakdowns than traditional equipment. Regular software updates and preventive maintenance ensure smooth operations, reducing downtime and costly repairs. With fewer interruptions, manufacturers can maintain a steady production flow, meet customer demands more efficiently, and increase overall profitability.

Conclusion

CNC Machining Service is a game-changer for businesses seeking to improve their production efficiency. From enhancing precision and speeding up processes to reducing waste, increasing flexibility, and improving workplace safety, CNC machining provides a range of benefits that optimize manufacturing operations. By integrating CNC technology into production workflows, companies can achieve higher output, lower costs, and maintain a competitive edge in their respective industries.

English

English