Everything You Need To Know About Cement Bulker And More

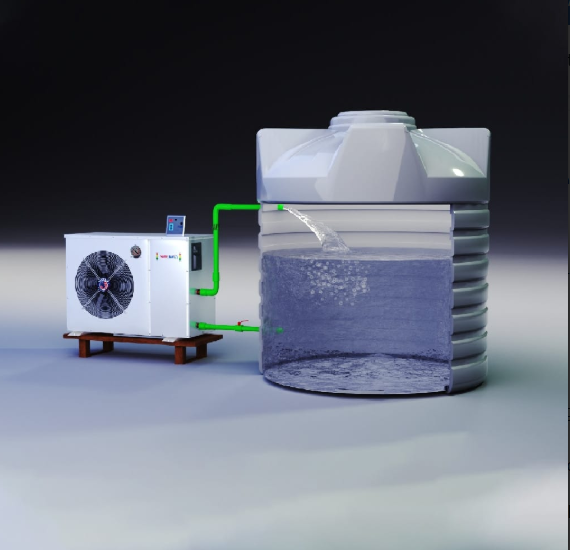

A cement bulker is a bulk dealing equipment that is used to store and transport a massive amount of cement from one point to the other, rather than cement bags. It can actually hold tonnes of cement.

It is basically a specialized semi-trailer. It transports particles like cement, coal dust, stone dust, flour, and chemical granules. It is majorly used in industry, agriculture, commerce, power plants, construction, and other industries. The tanker body has a large volume and good sealing. It might be dust-proof and does not need too much manpower. The most common use of these includes cement warehouses, cement plants, and large construction sites.

Let us take a deep dive and see what you need to know about a cement bulker.

What is a cement bulker?

A cement bulker, also known as a cement trailer or a cement tanker, is a specialized transportation vehicle designed to transport bulk cement from factories or distribution centers to construction sites.

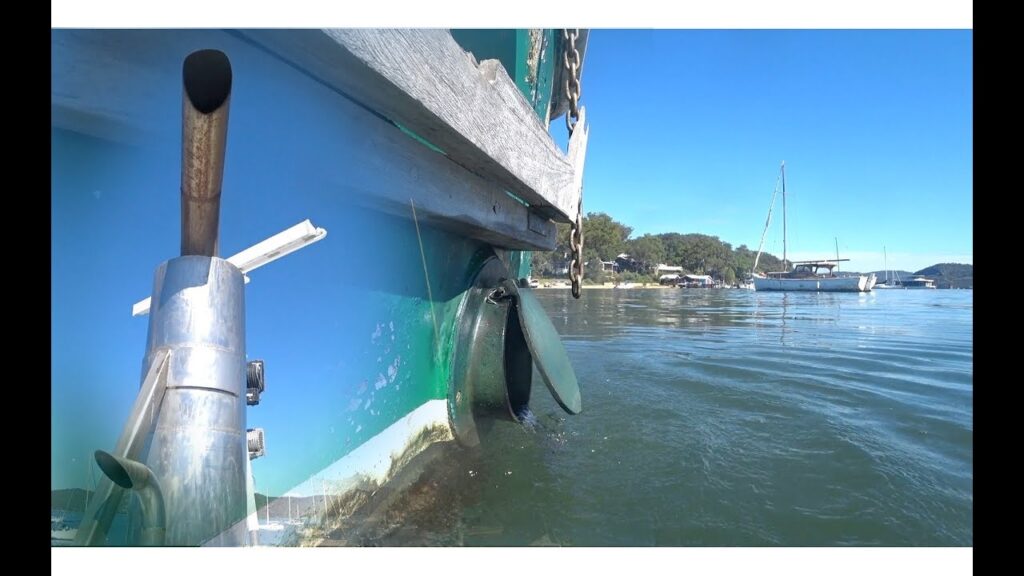

The trailers generally have a large cylindrical tank that can hold up to 50 to 120 tons of dry bulk materials such as cement, fly ash, and lime powder. The tank is generally made of steel and has a series of compartments with air compressors and valves that allow the operator to control the discharge of the material.

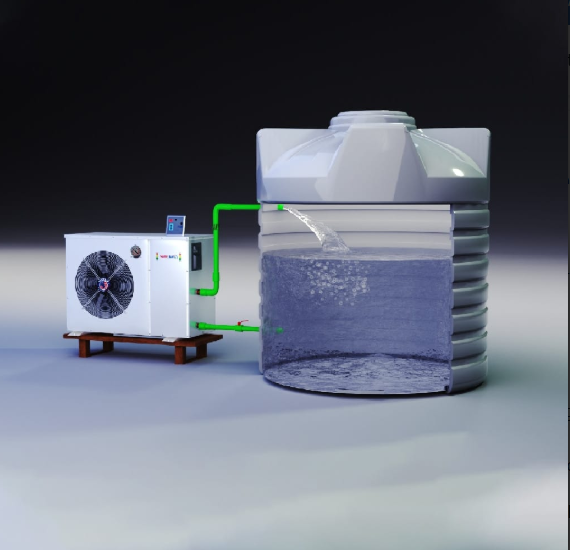

The cement bulker price uses its own engine to drive the onboard air compressor and sends compressed air through the pipeline to the air chamber at the bottom of the sealed tank so that the cement on the fluidized bed is suspended in a fluid state.

Uses of cement bulker

The main purpose is to transport bulk materials like cement, lime, or sand with a diameter of less than 0.1 mm. This is also the best way to transport cement. It may transport massive amounts of cement from the manufacturer to the concrete batching plant, and this method is far better than using cement bags. Because the bulk carrier is airtight, it can prevent the cement from being exposed to the environment.

At the same time, cement bulk trailers can also be used as temporary storage units. If you use cement bags, it will increase the workload and time.

Benefits of cement bulker

Let us have a look at the advantages of a cement bulker:

- High transportation efficiency: Loading and unloading is simple and easy using compressed air directly. No excessive human involvement is needed. This can greatly reduce labour consumption.

- Saving packaging materials: There is no requirement to pack the powder during transportation. This can reduce packaging costs and save transportation costs.

- Loss cargo loss: Compared with bagged transportation, the loss rate of power can transportation is smaller, generally below 0.5%. It can massively decrease the cargo damage caused by moisture.

- Reduce environmental pollution: Transporting powder tanks might reduce packing waste and save resources. It can also reduce particle pollution during transportation.

Industrial uses

The construction industry often uses large amounts of concrete. The cement bulker trailer can transport large quantities of concrete in a single trip to meet the needs. Its efficient loading and unloading might help decrease the construction time and increase productivity.

The cement bulker truck trailer is mobile and may load a lot of cargo at once. Thanks to the hermetic seal of the tank, it might be transported in bad weather. These semi-trailers are very famous in the logistics industry.

Wrapping Up

Remember, the cement bulker truck trailer has an inlet above the tank, and a gas chamber fluidized bed inside the tank. When discharging, the compressed gas fluidizes the power in the closed tank and then ‘blows’ it out. The tank bottom will tilt to help power flow. For powders with poor fluidity, the tilt angle will lift them.

That being said, choosing the right bulker means no walking in the park. You have to know the essentials and understand your needs. Consider checking out N.A.Z Industries LLC for further help.

English

English