Introduction

In the world of welding, safety should be a top priority. Welders are exposed to various hazards, including intense heat, bright light, harmful fumes, and the risk of electrical shocks or burns. One of the most critical tools in a welder’s arsenal is the MIG (Metal Inert Gas) welding torch. This essential piece of equipment plays a crucial role in ensuring a safe and efficient welding process. However, not all MIG welding torches are created equal. To enhance welding safety and promote a secure working environment, it’s essential to choose a high-quality MIG welding torch that incorporates advanced safety features. In this blog post, we’ll explore the key features to look for in a quality MIG welding torch and how they can contribute to a safer welding experience.

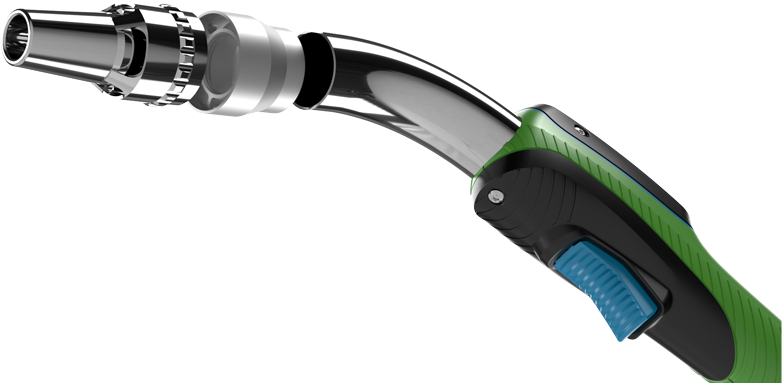

Ergonomic Design

Prolonged use of a welding torch can lead to fatigue, discomfort, and potential injuries, especially in the hands, wrists, and arms. An ergonomic design should be a top priority when selecting a MIG welding torch. Look for torches that feature lightweight yet durable materials, well-balanced weight distribution, and contoured grips that conform to the natural shape of the hand. These ergonomic features can help reduce strain, improve control, and minimize the risk of repetitive stress injuries.

Integrated Safety Controls

Advanced MIG welding torches often incorporate integrated safety controls that allow welders to adjust settings and monitor crucial parameters without interrupting the welding process. Look for torches with user-friendly controls that enable easy adjustment of wire feed speed, voltage, and amperage, ensuring optimal performance and safety. Additionally, some torches may feature built-in displays or indicators that provide real-time feedback on welding conditions, allowing welders to make informed decisions and take corrective actions when necessary.

Heat Management Systems

Excessive heat is a common hazard in welding, and prolonged exposure can lead to burns, discomfort, and potential equipment damage. Quality MIG welding torches should incorporate effective heat management systems to protect both the operator and the torch itself. Look for torches with heat-resistant materials, insulated handles, and advanced cooling mechanisms that dissipate heat away from the operator’s grip. These features can help prevent burns, reduce the risk of heat-related injuries, and extend the lifespan of the torch.

Fume Extraction and Ventilation

Welding fumes are a significant health concern, as they can contain harmful particulates and gases that can cause respiratory issues and long-term health complications. To mitigate this risk, some MIG welding torches feature integrated fume extraction systems that capture and remove fumes at the source. Look for torches with built-in extraction nozzles or ports that connect to external ventilation systems, ensuring a safer and healthier working environment for welders.

Arc Safety Features

Arc flash and electrical shocks are serious hazards in the welding industry, and proper safety measures are essential. Quality MIG welding torches may incorporate advanced arc safety features to protect welders from these risks. Look for torches with insulated designs that minimize the risk of electric shocks, as well as features like arc detection sensors or automatic shutoff mechanisms that can help prevent arc flash incidents.

Durability and Reliability

Welding environments can be harsh and demanding, subjecting equipment to various stresses and potential damage. When selecting a MIG welding torch, durability and reliability should be key considerations. Look for torches constructed from high-quality materials that can withstand the rigors of welding, such as impact-resistant housings, strain-relief cable connections, and reinforced components. Additionally, consider the manufacturer’s reputation for quality and the availability of replacement parts or service support.

Compatibility and Connectivity

Modern welding operations often involve the integration of various equipment and systems. When choosing a MIG welding torch, ensure compatibility with your existing welding machines, power sources, and any additional accessories or peripherals you may be using. Some torches may offer advanced connectivity features, such as digital interfaces or wireless communication capabilities, allowing for seamless integration and remote monitoring or control.

User-Friendly Operation

Ease of use is an essential factor when it comes to welding safety. A user-friendly MIG welding torch can help reduce the risk of operator errors, improve efficiency, and enhance overall safety. Look for torches with intuitive controls, clear labeling, and well-designed interfaces that minimize confusion or misunderstandings. Additionally, consider the availability of comprehensive user manuals, training resources, or support from the manufacturer to ensure proper operation and maintenance.

Brand Reputation and Quality Assurance

When investing in a high-quality MIG welding torch, it’s crucial to consider the brand reputation and quality assurance standards of the manufacturer. Reputable brands are more likely to adhere to rigorous safety standards, employ strict quality control processes, and stand behind their products with warranties or customer support. Research the manufacturer’s track record, industry certifications, and customer reviews to ensure you’re selecting a trusted and reliable product.

Translas: Pioneering Integrated Fume Extraction in MIG Welding Torches

At the forefront of innovative fume extraction solutions for MIG welding applications is Translas, a renowned Dutch manufacturer of cutting-edge welding torches and equipment. Translas has developed a game-changing line of MIG welding torches that feature built-in welding fume extraction systems, designed to capture an impressive 98% of hazardous welding fumes directly at the point of generation. By seamlessly integrating the fume extraction technology into the torch itself, Translas has created a groundbreaking solution that prioritizes worker safety and promotes a cleaner, healthier work environment. These advanced torches not only exemplify the future of occupational safety in welding but also align with the industry’s focus on sustainable and responsible practices, making Translas a frontrunner in the development of cutting-edge MIG welding torch technology.

Conclusion

Enhancing welding safety is a continuous pursuit, and choosing the right MIG welding torch can play a crucial role in creating a secure and efficient welding environment. By prioritizing features such as ergonomic design, integrated safety controls, heat management systems, fume extraction, arc safety, durability, compatibility, user-friendliness, and brand reputation, welders can minimize risks and perform their tasks with confidence.

Invest in a quality MIG welding torch that meets the highest safety standards and incorporates advanced features tailored to your specific welding needs. Remember, prioritizing safety not only protects welders but also contributes to improved productivity, quality, and overall operational efficiency.

By embracing the latest advancements in welding torch technology and implementing robust safety protocols, businesses can cultivate a culture of safety while ensuring optimal performance and long-term success in the welding industry.